Calcining and sintering (rotary drum):

- Product sizes 100 mesh (150 µm) to 0.5 inch

- Capacity up to 10 tons per day (TPD)

- Firing temperature up to 3,000° F

- LOI down to 1.0%

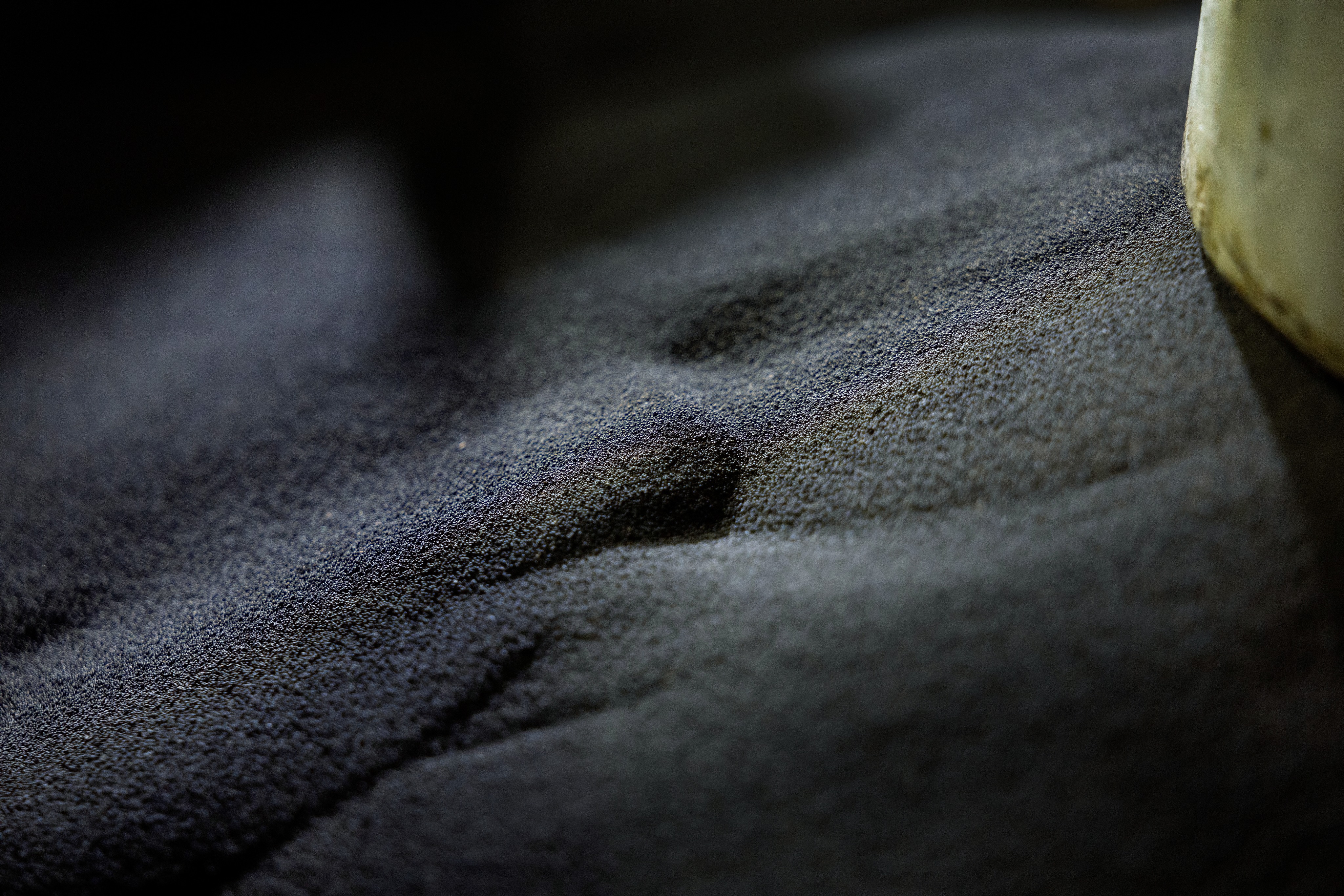

Blending dry bulk materials

- Capacity up to 300 TPD

Chemical coating, infusing and drying (pug mill and fluid bed)

- Capacity up to 450 TPD

- Material heating and cooling

- Emissions control and waste water clarification

Slurry particle size manipulation (blunger, mill, centrifuge and screen)

- Particle size reduction from 4 inches down to 4 µm

- Capacity up to 20 TPD dependent on ore and solids

Pilot plant and laboratory

- Research and development

- Quality assurance

- Particle/pellet size analysis (CPA, SediGraph and sieve)

- Pellet crush and attrition testing

- Pellet hardness and stress load testing

- Material/pellet density and porosity analysis (bulk and absolute)

- Metals analysis (ICP)

- Research and development

- Quality assurance

- Particle/pellet size analysis (CPA, SediGraph and sieve)

- Pellet crush and attrition testing

- Pellet hardness and stress load testing

- Material/pellet density and porosity analysis (bulk and absolute)

- Metals analysis (ICP)

Calcining and sintering (rotary drum):

- Product sizes 100 mesh (150 µm) to 0.5 inch

- Capacity up to 10 tons per day (TPD)

- Firing temperature up to 3,000° F

- LOI down to 1.0%

Blending dry bulk materials

- Capacity up to 300 TPD

Chemical coating, infusing and drying (pug mill and fluid bed)

- Capacity up to 450 TPD

- Material heating and cooling

- Emissions control and waste water clarification

Slurry particle size manipulation (blunger, mill, centrifuge and screen)

- Particle size reduction from 4 inches down to 4 µm

- Capacity up to 20 TPD dependent on ore and solids

Pilot plant and laboratory

- Research and development

- Quality assurance

- Particle/pellet size analysis (CPA, SediGraph and sieve)

- Pellet crush and attrition testing

- Pellet hardness and stress load testing

- Material/pellet density and porosity analysis (bulk and absolute)

- Metals analysis (ICP)

- Research and development

- Quality assurance

- Particle/pellet size analysis (CPA, SediGraph and sieve)

- Pellet crush and attrition testing

- Pellet hardness and stress load testing

- Material/pellet density and porosity analysis (bulk and absolute)

- Metals analysis (ICP)