Introduction

The method of proppant transport in a hydraulic fracture significantly affects reservoir contact area and fracture conductivity. These are important factors that, in turn, impact the economic viability of an entire hydraulic fracturing treatment.

For low-viscosity fluids, proppant must occupy the middle ground between lightweight, high-transport features and superior conductivity, compared to sand of the equivalent size. There was a time when the traditional, conventional approach to hydraulic fracture design was considered a linear gel or cross-linked fluid system. Now, the use of slickwater fluid systems has grown significantly, as designs need to cope with increasingly complex fractures and operators pay more attention to environmental sensitivities.

Challenges in Slickwater Systems

However, slickwater systems are not without their drawbacks. They lack the ability to effectively suspend and trans port proppant in a fracture (and the wellbore), due to their relatively low viscosity. To circumvent these diminished transport capabilities, fracture designs must consist of low proppant concentrations (0.25-2.0 PPA, typically), which necessitate extremely large volumes of fluid for placement. Moreover, slickwater completion designs combine a significant amount of small mesh-size proppant (100 mesh and 40/70 mesh sand) into the pump schedules, to provide placement in these thin fluid systems, which negatively affects the overall conductivity of the proppant pack.

CARBOAIR Proppant Technology Development

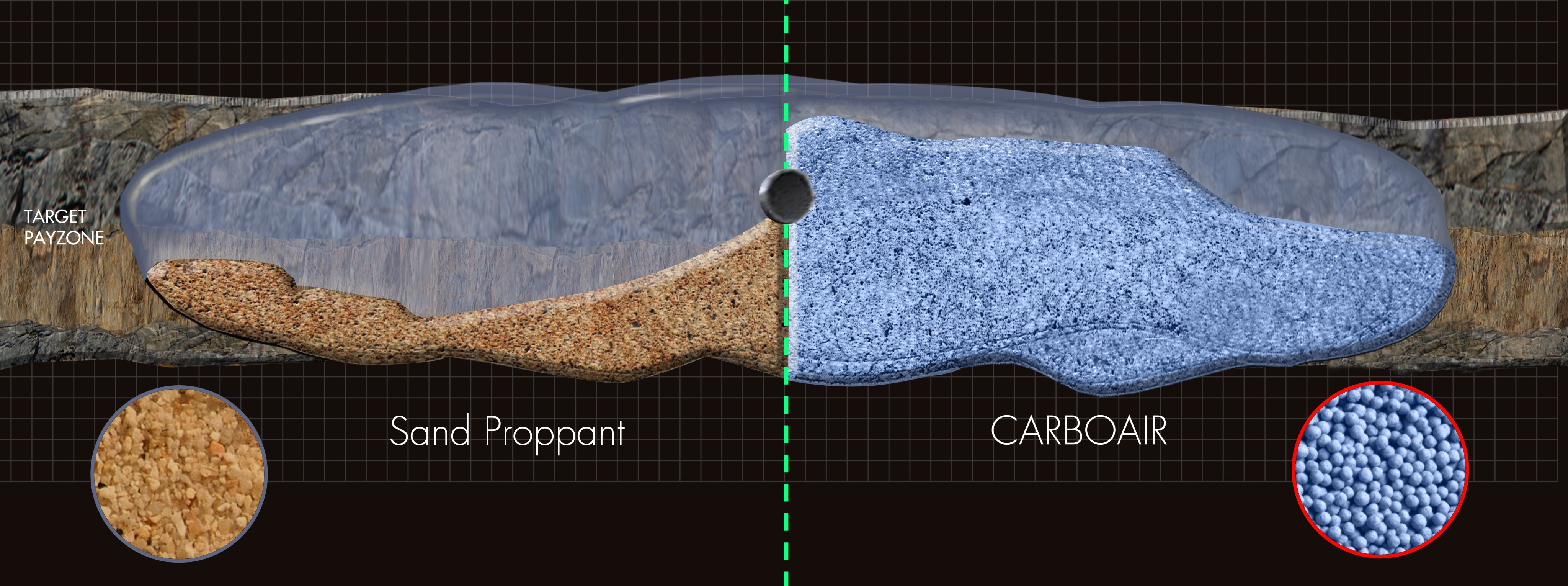

To mitigate this, CARBO developed CARBOAIR, a low-density proppant to enhance its transport capabilities in slickwater fluids, as well as provide in creased fracture conductivity. To date, higher production and EUR have been observed in the field, because of the higher fracture contact and conductivity delivered by the proppant, Fig. 1. Its lightweight characteristics allow it to achieve longer effective half-lengths and greater frac height.

Ultimately, the proppant enables operators to make use of more efficient completion designs with potentially smaller fracture designs (less proppant mass leading to less water, etc.), delivering the same or improved production.

TECHNOLOGY INSIGHT

CARBO developed the low-density proppant to be lighter than sand (for superior proppant transport) and more conductive at the closure pressures in which sand finds the most applicability. It has an apparent specific gravity of 2.0, which is approximately 25% lower than sand, resin-coated sand (RCS) or low-density ceramic (LDC), and provides about 35% more volume with the same mass com pared with sand, by virtue of their differences in bulk density.

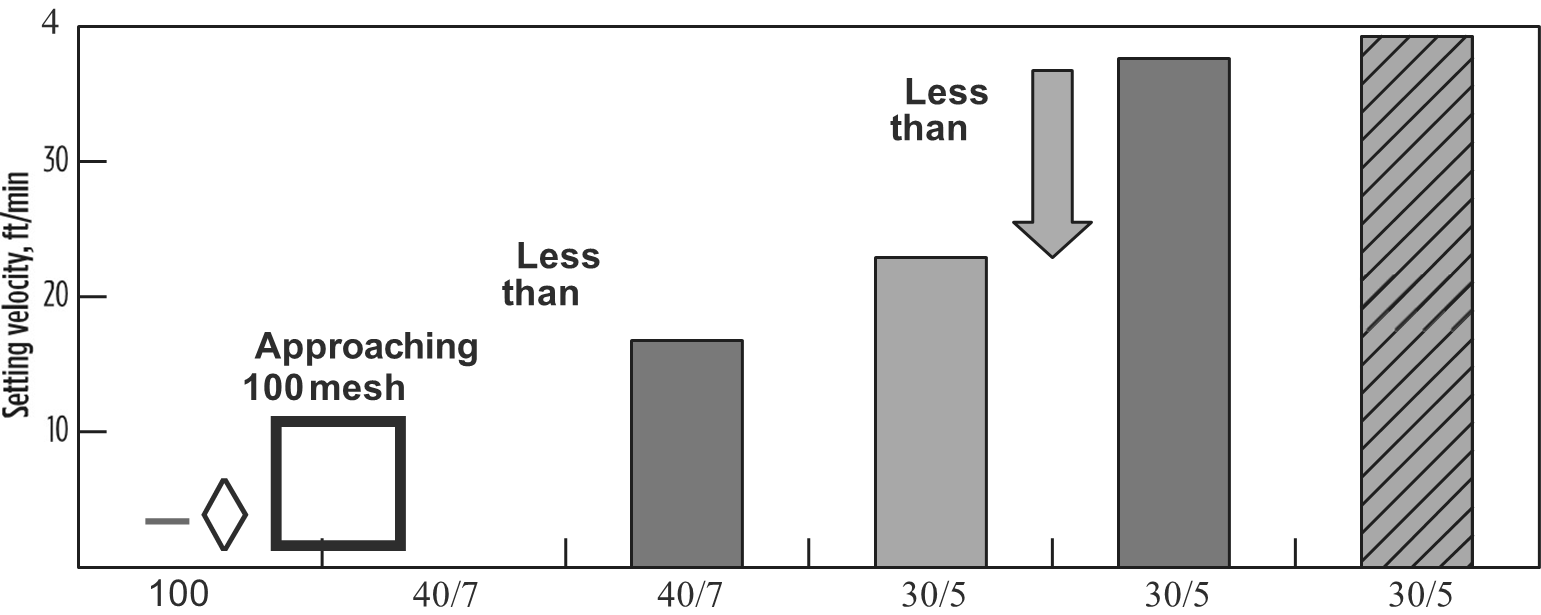

In short, within an equal-volume frac design, the technology requires less proppant mass to achieve the same propped fracture volume as conventional proppant. As a result, overall stimulation costs may be reduced, and the environmental impact of fracturing operations can be mitigated through less water consumption, less demand for pumping trucks and horsepower, and minimizing flowback treatment costs. It also features 30% to 40% slower settling rates compared to sand, lending to increased contact with the formation, which leads to higher pro duction, Fig. 2.

CASE STUDIES and RESULTS

A recent tail-in with CARBOAIR ceramic proppant improved reservoir drainage and extended the productive life of a well in New Mexico.

Challenge. The operator was looking to achieve the effective stimulation of a wildcat well with a thin gross pay (100-ft section gross interval) in New Mexico’s Bone Springs formation. The operator drilled this well, based on vertical open hole log data from a nearby well. While typical, high-pump-rate slickwater fracs with 100 mesh and 40/70 mesh sand are common in the area, there were no wells within 6 mi when this well was drilled. The goal of the design was to achieve a greater propped frac half-length in the formation to optimize contact with the thin gross pay, with the hope of flattening production decline in this marginal area.

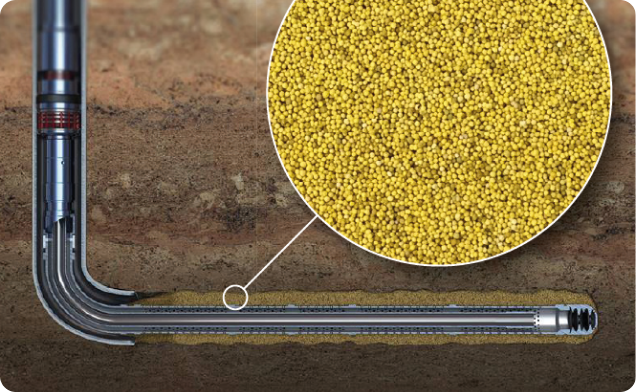

Solution. Approximately 2.5 MMlb of CARBOAIR were pumped as a tail-in to promote greater propped frac half length. Twenty-six frac stages were pumped, using a smaller amount (by weight) of CARBOAIR to achieve the equivalent volume as 40/70 convention al sand (ASG 2.65).

Results. Average daily oil production has remained stable, with the post-fracture decline rate proving to be shallower than other wells in the area. This was attributed to the increased contact area, due to the improved effectiveness and transportability of the CARBOAIR, as well as higher fracture conductivity. The well was put on artificial lift approximately nine months into production. Over the nine-month period, oil production averaged more than 300 bopd, with cumulative production of 130,000 hoe, to date.1

FURTHER APPLICATIONS

To date, the proppant has been pumped in tail-in applications in three major basins in the U.S.-the Permian, Northeast and South Texas. It also is being utilized in openhole gravel packs in Trinidad and continues to gain traction globally.

REFERENCES

- Jackson, K. and 0. Orekha, “Low density proppant in slick water applications improves reservoir contact and fracture complexity-A Permian basin case history,” SPE- paper 187498, September 2017.