CARBOTRACE

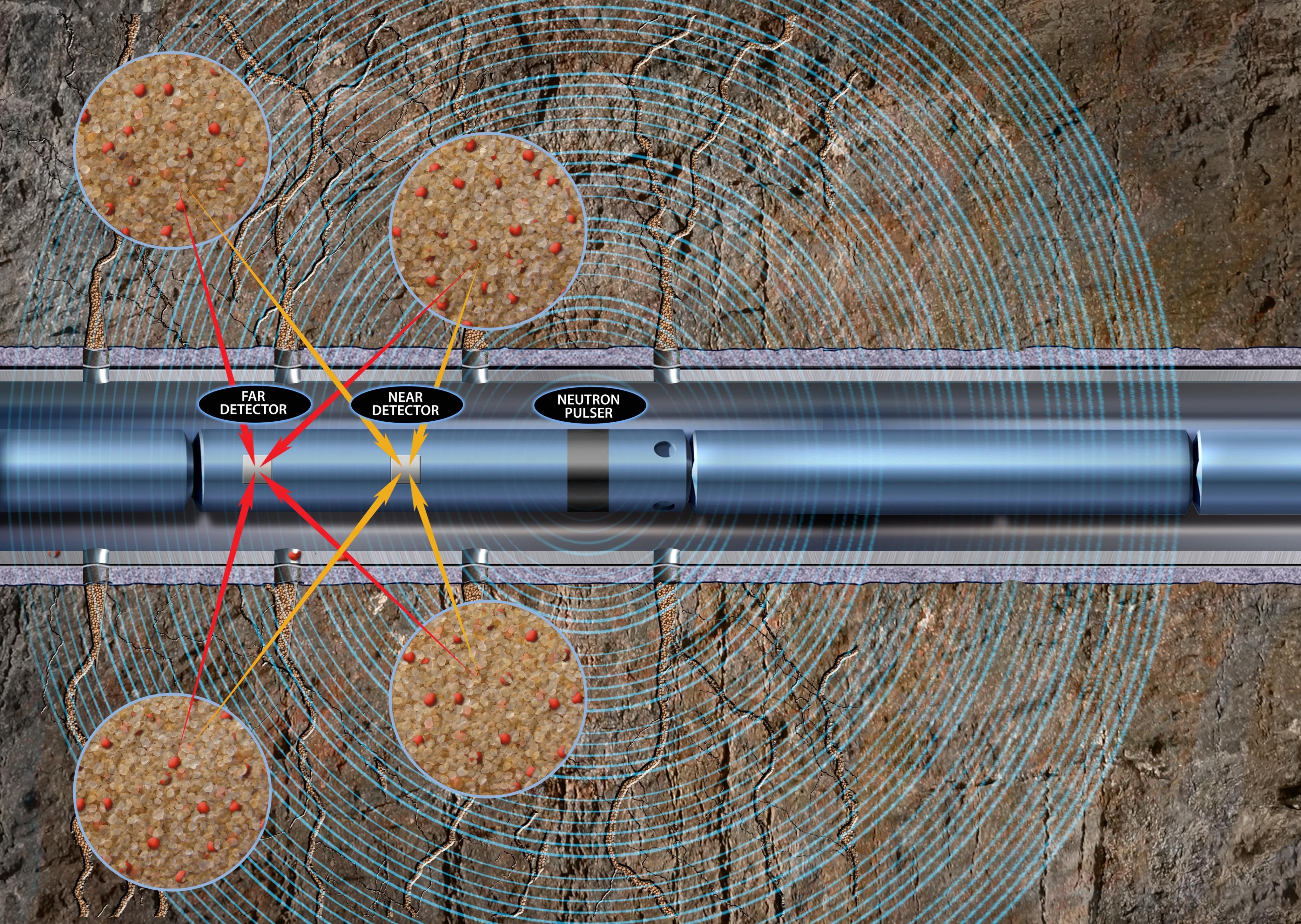

CARBOTRACE Production surveillance integrated with CARBO quality proppants. Deployed with any type and size of proppant, CARBOTRACE offers a quantitative analysis of the fraction contribution of the oil, water and gas phases for each frac stage.