Industrial sand serves as a cornerstone material across numerous manufacturing industries, enabling everything from energy extraction to precision metal casting operations. As global demand for higher-performance materials continues to escalate, manufacturers face increasing pressure to adopt solutions that deliver superior results while addressing safety and environmental concerns. The industrial sand landscape is rapidly evolving, with engineered alternatives emerging to solve longstanding challenges in traditional applications. This transformation spans multiple sectors, from hydraulic fracturing operations requiring exceptional conductivity to foundry applications demanding precise dimensional control and enhanced worker protection.

Industrial Sand Applications in Modern Manufacturing

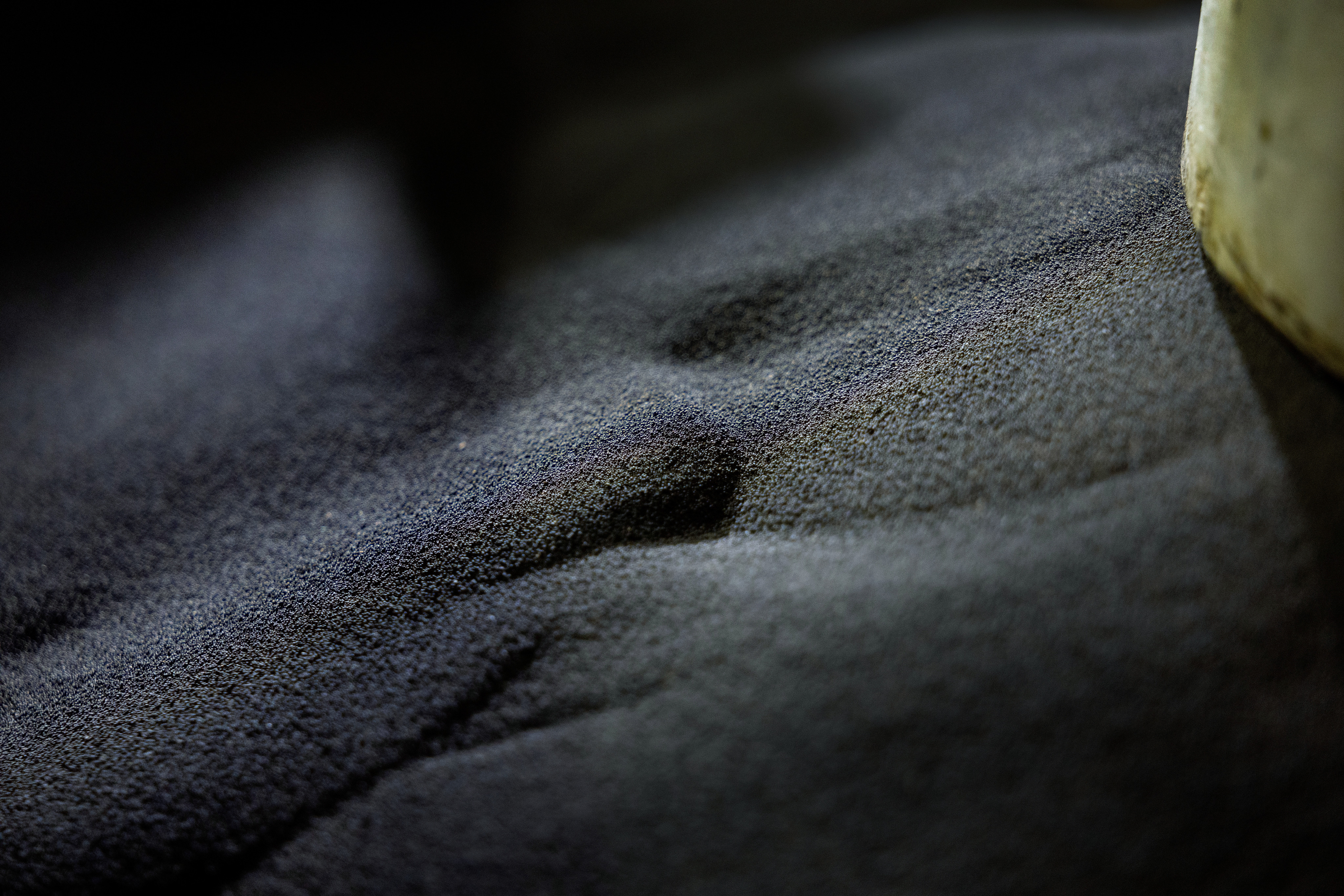

Industrial sand encompasses specialty sands that are high-purity silica materials engineered for demanding manufacturing applications, unlike standard construction sand. It undergoes rigorous processing to achieve precise grain size, optimal shape, and exceptional purity. Primary applications include hydraulic fracturing operations in oil and gas extraction and mold creation in metal casting foundries, both requiring materials with specific thermal properties, chemical inertness, and mechanical strength.

Quality requirements for industrial sand include several critical factors:

- Precise grain size control and distribution

- Spherical particle geometry for optimal packing

- High silica content with minimal impurities

- Thermal stability under extreme temperatures

- Chemical inertness to prevent contamination

- Mechanical strength to resist crushing forces

However, traditional industrial sand faces mounting challenges including supply chain vulnerabilities, escalating safety regulations, and performance limitations under increasingly demanding operational conditions.

Hydraulic Fracturing Applications

In oil and gas extraction, industrial sand serves as a critical proppant material that keeps fractures open after hydraulic stimulation treatments. Sand particles prop open newly created fractures in reservoir rock, creating pathways for hydrocarbon flow to production wells.

Frac sand effectiveness depends on three key properties:

- Conductivity determines flow efficiency through fracture networks

- Crush resistance maintains particle integrity under extreme pressure (up to 10,000+ psi)

- Spherical shape maximizes pore space and optimizes flow characteristics

Traditional sand faces significant limitations in high-pressure, high-temperature environments. Standard silica sand degrades at closure stresses above 6,000 psi, causing particle crushing that reduces conductivity and impairs well performance. Irregular grain shapes also create suboptimal packing that limits flow efficiency.

API standards establish specifications for grain size distribution, roundness, sphericity, and crush resistance. Common mesh sizes (20/40, 30/50, 40/70, and 100 mesh) are optimized for specific reservoir conditions. Operations require logistics infrastructure, with Class 1 railroads connecting sand sources to drilling locations nationwide.

Metal Casting and Foundry Applications

Traditional foundry casting operations rely on silica sand for creating molds and cores in sand casting processes, providing the structural framework that shapes molten metals into precision components from automotive parts to industrial machinery. However, mounting safety concerns regarding respirable crystalline silica exposure have fundamentally altered the foundry sand landscape, as prolonged inhalation can cause silicosis and has prompted stringent OSHA regulations.

Beyond safety considerations, traditional silica sand presents several performance challenges:

- Thermal expansion inconsistencies leading to dimensional variations

- Surface finish limitations affecting casting quality

- Burn-on conditions compromising component surfaces

- Veining defects from thermal expansion mismatches

- Limited reusability increasing material costs

- Moisture sensitivity affecting mold stability

Engineered ceramic media has emerged as an advanced alternative to traditional silica sand, offering superior performance characteristics while eliminating health and safety concerns. The exceptional dimensional stability, premium surface finish quality, and optimized thermal properties make these materials ideal for enhanced casting precision. Additionally, ceramic alternatives provide extended service life through superior durability and resistance to thermal degradation.

Ceramic Technology: Transforming Industrial Sand Performance

Engineered ceramic media represents the next evolution in industrial sands, combining exceptional strength, thermal stability, and chemical inertness to outperform traditional sand while delivering enhanced safety and sustainability benefits. In energy applications, ceramic alternatives provide superior conductivity and crush resistance, maintaining structural integrity under extreme downhole conditions with uniform spherical geometry that optimizes flow characteristics. For foundry operations, ceramic media eliminates respirable silica exposure while delivering substantial performance improvements in production efficiency, operational costs, and casting defect reduction.

Key advantages of ceramic alternatives include:

- Complete elimination of silica dust exposure risks

- Enhanced thermal stability for consistent performance

- Superior dimensional accuracy and surface finish quality

- Extended service life through improved durability

- Reduced waste generation and disposal costs

- Improved recyclability for sustainable operations

Sustainability advantages include significantly longer material service life, reduced waste generation, and improved recyclability compared to traditional sand. The durability of ceramic media enables multiple reuse cycles, reducing material consumption and disposal costs while minimizing environmental impact.

Choosing the Right Ceramic Solution

The industrial sand landscape continues evolving as manufacturers seek higher-performance solutions that address safety, sustainability, and operational efficiency requirements. While traditional sand remains viable for many applications, engineered ceramic alternatives offer compelling advantages for demanding operations requiring superior performance and enhanced safety profiles. Success in today’s competitive manufacturing environment increasingly depends on selecting materials optimized for specific application requirements, with engineered solutions representing the future of industrial sand technology.

CARBO Ceramics: Your Partner in Advanced Industrial Sand Solutions

For nearly five decades, CARBO Ceramics has stood at the forefront of industrial sand technology, engineering advanced ceramic solutions that transform manufacturing efficiency, safety, and sustainability across global industries. Founded in 1979 and proudly American-made, CARBO has evolved from a pioneering ceramic proppant manufacturer to a provider of engineered industrial sand alternatives serving customers in over 120 countries worldwide through state-of-the-art manufacturing facilities strategically located across the United States.

As an American manufacturer with global reach, we take pride in our track record of innovation and safety leadership, with our diverse workforce spanning 15 nationalities bringing unique perspectives to solving complex industrial challenges. Through ongoing innovation and unwavering dedication to quality, CARBO continues to help customers achieve new levels of operational excellence while improving environmental sustainability, enabling manufacturers to achieve superior results in both energy and foundry applications for success in an increasingly competitive global marketplace.

Frequently Asked Questions

What is industrial sand and how is it different from regular sand?

Industrial sands are high-purity silica sands engineered for demanding manufacturing applications with precise grain sizes, shapes, and purity specifications. Unlike construction sand, it undergoes rigorous processing for optimal performance in hydraulic fracturing and metal casting operations.

What industries use industrial sand?

Primary industries include oil and gas (hydraulic fracturing) and metal casting foundries. It’s also used in glass manufacturing, construction, filtration systems, and specialty applications requiring specific performance characteristics.

Why are companies switching from traditional sand to ceramic alternatives?

Traditional silica sand poses health risks through respirable crystalline silica exposure. Ceramic alternatives eliminate safety concerns while delivering superior thermal stability, dimensional accuracy, and longer service life..