Introduction

Fracture-stimulation designs and cost structures are continually evolving in unconventional reservoirs. Consequently, slickwater fracturing fluids are being deployed more frequently because they cost less, have a reduced impact on proppant pack damage, and have reduced chemical package requirements. However, the low viscosity of these fluids negatively affects proppant- carrying capacity, making proppant transport and placement a problem when designing an optimized, effective stimulation. Because slickwater treatments are subject to limitations in proppant maximum concentration, the result can be lower fracture conductivity.

What is CARBOAIR?

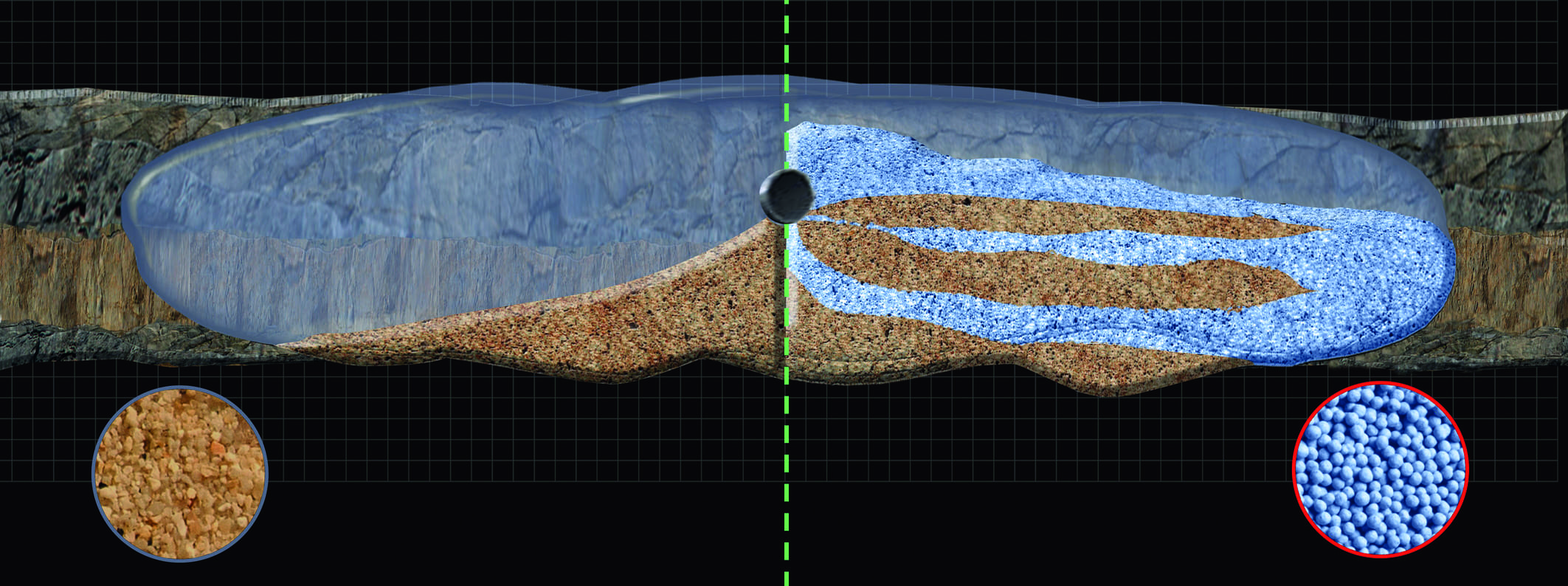

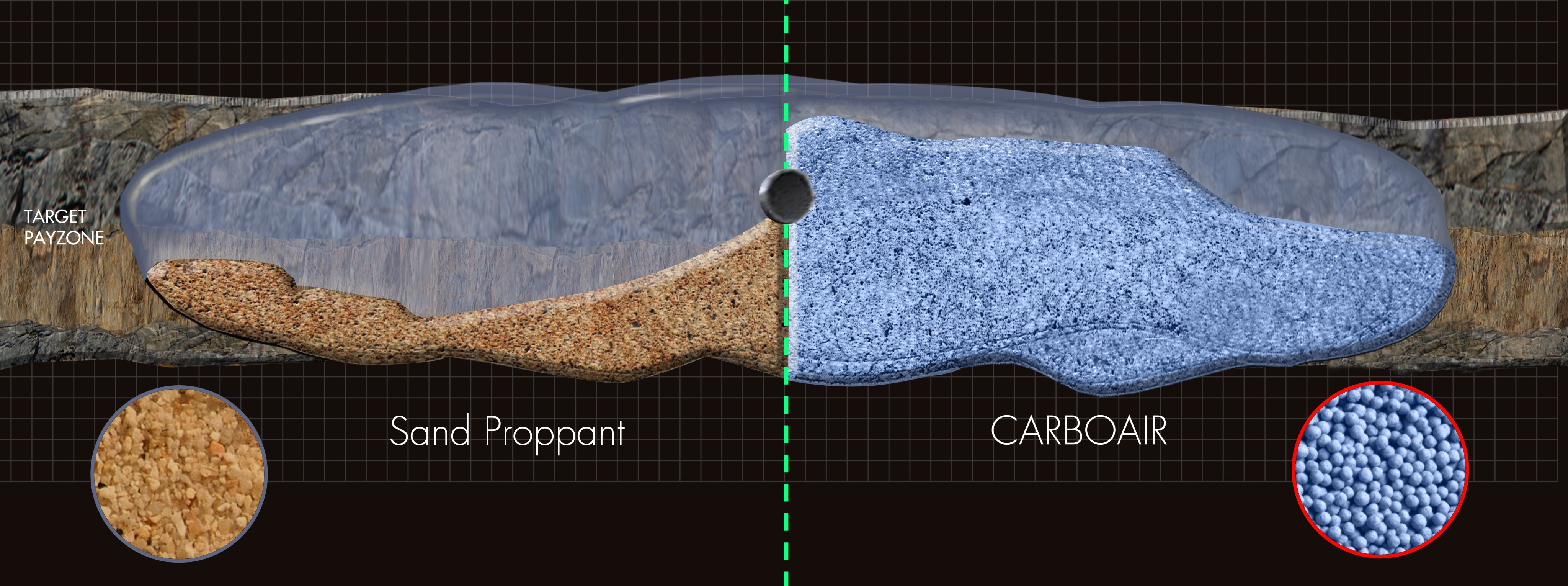

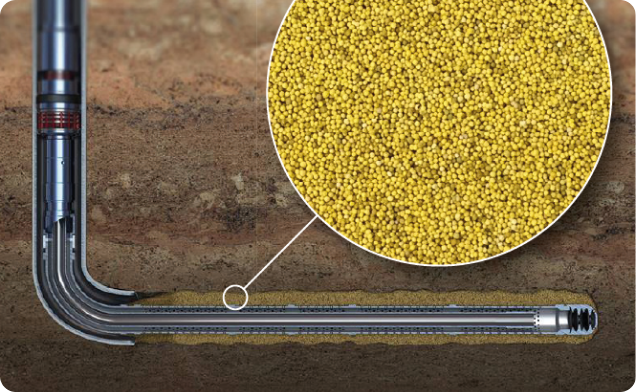

CARBOAIR is a new high-transport, ultralow-density ceramic-proppant technology developed by CARB O. With chemically engineered internal porosity, CARBOAIR is designed to maximize production and estimated ultimate recovery from slickwater fracturing operations. CARBOAIR, with a 30 to 40% lower settling rate compared with sand or resin- coated sand, is able to increase the propped fracture height and length over a range of applications, maximizing the effective fracture contact area and conductivity. The technology has been proven to deliver better proppant transport, propped fracture geometry (length and height), fracture conductivity, and reservoir contact area compared with conventional sand, increasing production and adding value for operators working across a variety of formations.

Image Description: Alternating CARBOAIR technology with standard proppant within a fracturing stage using slickwater fluids can provide increased effective propped length as well as full productive zone coverage, leading to additional production and ultimate recovery.

Copyright 2017, Society of Petroleum Engineers. Reprinted from the Journal of Petroleum Technology with permission.