Surface Modification Technology

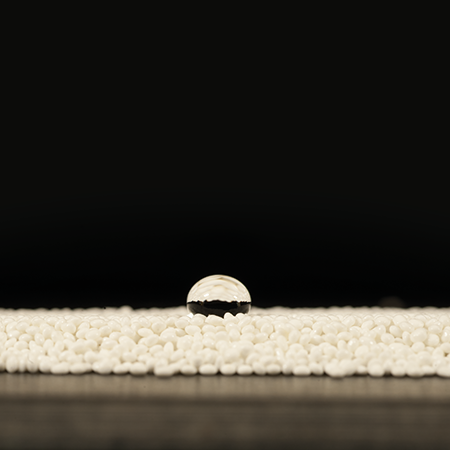

NEUTRALWET modifies the surface of treated proppants to achieve neutral wettability with a contact angle of approximately 90°, enhancing flow efficiency.

A Breakthrough in Wettability Modification

NEUTRALWET relative permeability modification technology is engineered to alter the wettability of proppant to neutral, preventing the retention of water-based fluid in the proppant pack. NEUTRALWET technology increases the effective fracture length, conductivity and permeability of the pack to hydrocarbons, leading to higher production and increased ultimate recovery.

Remove capillary effects

Most conventional proppant is strongly water wet, exhibiting a contact angle < 90°. This allows for easy wetting and dispersion of the water-based fracturing fluids in the fracture, causing them to become trapped in the pore throats of the proppant pack.

NEUTRALWET technology alters the wettability of the proppant surface to neutral. This leads to a contact angle of ~90°, which virtually eliminates capillary forces that prevent water and water-based fracture fluids from becoming trapped after fracturing and during production. This leads to an increased hydrocarbon permeability.

BENEFITS

Enhanced Production Rates

NEUTRALWET increases oil and gas production by improving the clean-up of water-based fracture fluids after stimulation.

Prevents Fluid Trapping

By preventing water-based fluids from becoming trapped in proppant pack pore throats, NEUTRALWET maintains optimal flow conditions.

Increases Fracture Efficiency

It enhances effective fracture length, conductivity, and permeability, maximizing hydrocarbon flow and recovery.

Reduces Pressure Drop

NEUTRALWET minimizes pressure drop from multiphase flow effects, improving flow rates and efficiency.

Features

NEUTRALWET modifies the surface of treated proppants to achieve neutral wettability with a contact angle of approximately 90°, enhancing flow efficiency.

The coating remains stable at temperatures up to 400°F (205°C), making NEUTRALWET suitable for use in a wide range of wells.

NEUTRALWET-treated proppants are compatible with various fracturing fluids, ensuring seamless integration into existing operations.

Available as a flow enhancement option for any CARBO ceramic proppant, NEUTRALWET supports flexibility in proppant selection.

Frequently Asked Questions

What is NEUTRALWET technology used for?

NEUTRALWET is a relative permeability modification technology that alters proppant wettability to neutral, helping prevent the retention of water-based fluids in the proppant pack and enhancing hydrocarbon flow.

How does NEUTRALWET increase oil and gas production

By eliminating capillary forces and preventing fluid trapping, NEUTRALWET increases effective fracture length, conductivity, and permeability, ultimately improving hydrocarbon flow and production rates.

What makes NEUTRALWET effective for water-based fractures?

NEUTRALWET-treated proppant modifies surface wettability to a neutral contact angle (~90°), which minimizes capillary forces and enhances the clean-up of water-based fracture fluids after stimulation.

What types of proppants can NEUTRALWET be applied to?

NEUTRALWET technology can be applied to any CARBO ceramic proppant, offering flexibility in proppant selection for different applications.

How does NEUTRALWET technology improve fracture clean-up?

By reducing fluid retention in the proppant pack and lowering capillary pressures, NEUTRALWET enhances fracture fluid clean-up and reduces conductivity impairment from gel damage.

Get access

Please fill out the form to continue reading

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.

Get access

Please fill out the form to continue reading

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.

Join Us

Subscribe our newsletter and stay

up to date about the company

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.