NANOMITE

The unique characteristics of NANOMITE ceramic microproppant reduces completion time, screen-out risks, and overall completion costs while improving the production contribution from all clusters and the reservoir matrix.

NANOMITE microproppant delivers numerous benefits during stimulation that increase efficiency and well productivity:

- Overcomes fracture entry restrictions

- Lowers high surface treating pressures

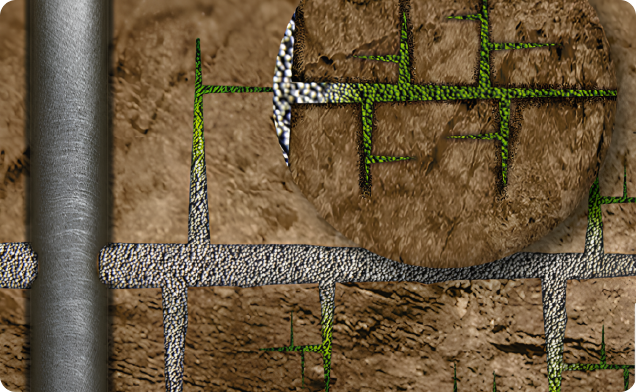

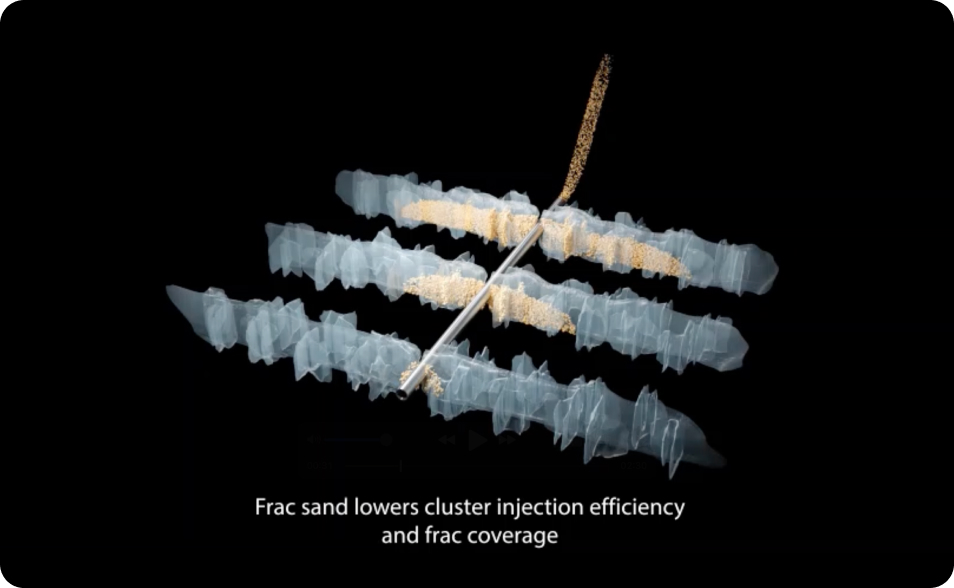

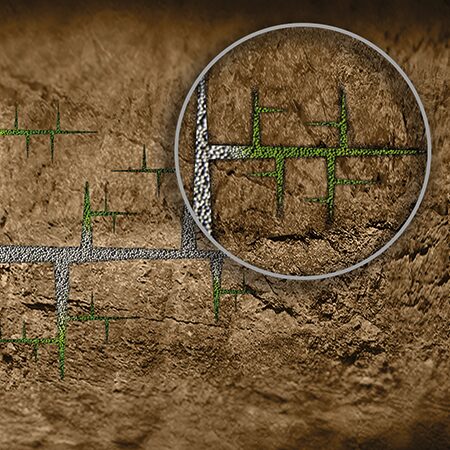

- Improves cluster injection efficiency

- Increases propped reservoir contact area

- Increases production and recovery

Reduce completion time, screen-out risks, and overall completion costs

NANOMITE microproppant overcomes fracture entry restrictions in the perforations and near-wellbore area through erosion of restrictions and improves near-wellbore diversion resulting in reduced surface treating pressures. As a result, reduced pumping pressures can be realized, or lower pumping times are required due to increased injection rates, that lower completion time and overall completion costs. The removal of entry restrictions lowers screen-out risks.

Outperform alternative products

NANOMITE microproppant delivers, operational, performance, and cost benefi ts compared to alternative, along with minimized health concerns associated with exposure to dust.

NANOMITE microproppant is easily incorporated in stimulation treatment designs. The microproppant is pumped as the fi rst proppant in a thin fl uid system at a low slurry concentration (0.10 to 0.25 lb/gal) to maximize the depth of the microproppant penetration into the fracture.

Excellent proppant transport characteristics due to a wide range of settling velocities

NANOMITE ceramic microproppant contains a broad range of particle sizes within the 150/635 mesh (100 μm to 20 μm) range. The smallest NANOMITE particles are over five times smaller than the smallest particles in 100 mesh frac sand.

NANOMITE microproppant has superior transport and settling characteristics in thin fluid systems (freshwater or slickwater) so travel farther into complex fracture networks to release production from otherwise untapped microfractures. The average settling rate of 100 mesh sand is over twice as fast as NANOMITE particles.

All Product Files

Get access

Please fill out the form to continue reading

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.

Benefits

Why Choose

NANOMITE

-

Increased EUR and maximize production

-

More erosive to fracture entry restrictions than 100 mesh sand

-

Superior transport characteristics to travels further into complex fracture networks

-

Props secondary and microfractures to increase long-term well productivity

-

Survives impact forces during pumping and withstands high fracture closure stresses

-

Can be added during pad stage without disrupting established routines

Features

Advanced Attributes

of NANOMITE

-

Extremely small microproppant particles

-

Broad size range for optimum operational flow and reach

-

Low settling velocity due to the wide range of particle sizes

-

Strong and durable ceramic particles

Case Studies

Discover the Impact of

Our Ceramic Solutions

Resources

Comprehensive

Knowledge Hub

Frequently Asked Questions

Learn more about

NANOMITE

-

1. What is NANOMITE® used for?

NANOMITE is a high-performance ceramic proppant designed for ultra-fine proppant applications in hydraulic fracturing, improving conductivity in tight formations.

-

2. How does NANOMITE enhance well productivity?

Its small particle size ensures better fracture coverage, improving hydrocarbon flow in tight shale and unconventional reservoirs.

-

3. What types of reservoirs benefit most from NANOMITE?

It is ideal for ultra-tight and low-permeability formations where fine particles are necessary for effective proppant placement.

-

4. How does it compare to traditional proppants?

NANOMITE offers higher conductivity and better fracture penetration compared to standard-sized ceramic proppants.

-

5. Is it compatible with all fracturing fluids?

Yes, NANOMITE integrates smoothly with various fracturing fluids, providing operational flexibility.

-

6. How does NANOMITE improve operational efficiency?

Its fine size enhances proppant transport, reducing fluid viscosity requirements and improving fracture coverage.

-

7. Can NANOMITE prevent proppant flowback?

Its particle distribution ensures a stable pack, reducing the risk of flowback and maintaining well integrity.

-

8. Is it environmentally safe?

Yes, NANOMITE is chemically inert, promoting safe use and minimizing environmental impact.

-

9. What industries benefit from NANOMITE?

It is particularly effective in oil and gas operations targeting tight shale and low-permeability formations.

Get access

Please fill out the form to continue reading

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.

Get access

Please fill out the form to continue reading

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.

Join Us

Subscribe our newsletter and stay

up to date about the company

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.