Inert, Permanent, and Environmentally Friendly Tracer

CARBONRT ULTRA features a safe, inert tracer that poses no environmental risks and requires no special equipment, handling, permits, or licenses, ensuring ease of use and regulatory compliance.

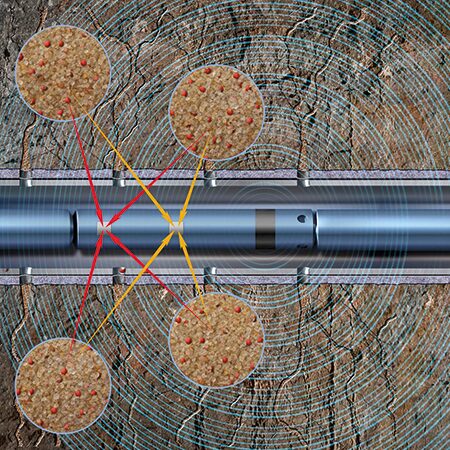

CARBONRT ULTRA inert tracer technology has been developed to enable the cost-effective fracture evaluation of sand completed wells to help you optimize completion efficiency, production and field development. The unique non-radioactive tracer (NRT) technology enables the effective detection and evaluation of near-wellbore proppant location and quantity using our FRACTUREVISION proppant-delivered fracture evaluation service at any time during the life of the well.

Enhanced tracer for effective detection within sand completed wells

CARBONRT ULTRA technology is a proppant that is manufactured with a variant of our unique tracer technology specifically engineered for use in sand completed wells. As the tracer is uniformly distributed throughout each proppant grain and integral to the proppant matrix it cannot be dissolved or washed away.

High quality measurements anytime with standard tools

Our unique technology features an inert traceable material that has a high neutron capture cross section which is detectable with a standard, cost-effective neutron logging tool run. This makes the result a direct measurement of where proppant is located, rather than an interpretation.

Determine propped fracture coverage and improve perforation efficiency

After fracturing it is critical to determine whether all zones have been stimulated as planned. If a particular zone is not producing, it is important to understand whether it is due to a poor reservoir quality or poor stimulation.

CARBONRT ULTRA technology can be used to evaluate how many perforations have taken proppant and been successfully stimulated in horizontal wells. In addition, the evaluation of perforations with our technology can be used to develop an understanding of duning effects.

Understand near-wellbore connectivity to avoid overflushing

CARBONRT ULTRA technology can measure the amount of proppant that is near the wellbore to provide you with an understanding of your near-wellbore connectivity.

Identify optimal stage spacing

In both vertical and horizontal wells, CARBONRT ULTRA technology can be used to pinpoint propped stage intervals and confirm successful stimulation.

Increase fracture geometry modeling accuracy

Pressure curves and measurements of pumped proppant volumes can be recorded during stimulation. When combined with propped fracture height and open perforations, measurements obtained with CARBONRT ULTRA technology can enhance the quality of your fracture simulator model and analysis.

Fracture height is used to calibrate the stresses above and below the formation, and, when used in conjunction with a fracture model, can give an indication of hydraulic fracture geometry.

Develop integrated solutions to calibrate propped fracture network and SRV models

The integration of proppant placement measurements obtained using CARBONRT ULTRA technology with diagnostic technologies such as microseismic, distributed temperature sensing, distributed acoustic sensing and production logs creates an integrated solution that enables you to calibrate your fracture network and SRV models. The model calibration enables you to calculate the propped fracture network and propped SRV.

Only CARBONRT ULTRA technology tracks proppant location which makes it an integral part of an integrated solution to understand where your treatment went and more importantly, why.

All Product Files

Public access files

Benefits

Cost-Effective Fracture Evaluation

CARBONRT ULTRA provides an economical solution for evaluating fractures in both vertical and horizontal sand-completed wells, allowing for more efficient and accurate assessments

Identifies Proppant Coverage and Fracture Height

The technology accurately identifies the stimulated interval and the propped fracture height, giving you a clear picture of proppant distribution and overall well performance.

Tracks Near-Wellbore Proppant

By tracking the amount of proppant near the wellbore, CARBONRT ULTRA helps you understand near-wellbore connectivity and perforation efficiency, leading to better completion outcomes.

Enhances Fracture Simulation Models

The data provided by CARBONRT ULTRA can be used to refine fracture simulation models, improve treatment designs, and optimize overall completion efficiency.

Case Studies

Features

CARBONRT ULTRA features a safe, inert tracer that poses no environmental risks and requires no special equipment, handling, permits, or licenses, ensuring ease of use and regulatory compliance.

The tracer is specifically designed to blend seamlessly with sand, ensuring reliable detection and consistent results during subsurface evaluations.

Unlike surface coatings, the tracer is uniformly distributed throughout each ceramic proppant grain, providing enhanced durability and the flexibility to be manufactured into any CARBO ceramic proppant product.

CARBONRT ULTRA is easily detected using standard neutron logging tools, operated at standard logging speeds, offering a simple and efficient way to track proppant placement and movement.

Frequently Asked Questions

1. What is CARBONRT® ULTRA used for?

CARBONRT ULTRA is designed for advanced reservoir evaluation, helping operators track proppant placement and optimize well performance.

2. How does it enhance well production?

Its built-in tracers allow for precise monitoring without disrupting operations, providing valuable insights into well efficiency and production.

3. Is it environmentally safe?

Yes, CARBONRT ULTRA integrates safely into oilfield operations without introducing hazardous materials.

4. How does CARBONRT® ULTRA integrate with other reservoir evaluation tools?

It seamlessly complements other logging and monitoring tools, enhancing data accuracy for production optimization.

5. What kind of reservoirs is CARBONRT ULTRA best suited for?

It is ideal for unconventional wells and complex formations where precise proppant tracking is critical.

6. Does it require special equipment for detection?

CARBONRT ULTRA can be tracked with standard gamma logging tools, streamlining operations without additional investments.

Get access

Please fill out the form to continue reading

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.

Get access

Please fill out the form to continue reading

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.

Join Us

Subscribe our newsletter and stay

up to date about the company

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.