Safe and Environmentally Friendly Tracer

An inert, permanent tracer that requires no special equipment, handling, permits, or licenses, making it both safe for operators and eco-friendly.

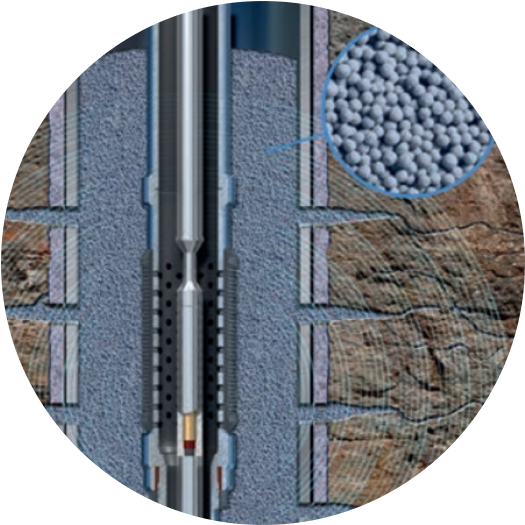

CARBONRT GP inert tracer technology for gravel pack applications has been developed to enable a safe, accurate and cost-effective evaluation of gravel pack completed wells. The technology is used in cased hole and open hole completions in both vertical and horizontal wells to help you increase production and recovery. The tracer is permanently detectable, so evaluations can be performed and repeated at any time during the life of the well to ensure sufficient pack quality.

Confirm productive zone coverage

Our tracer technology is used to detect the top of the gravel pack to confirm that the entire productive zone has been covered successfully in the near-wellbore region.

Assure gravel pack quality

CARBONRT GP technology allows you to identify the presence of any channels or voids in the pack by directly measuring the location of the proppant in the near-wellbore region during completion operations.

Identify fines and sand migration

The technology is used to identify if sand and fines have migrated from the formation into the gravel pack after months or even years of well production. The permanently detectable tracer enables you to perform log evaluations throughout the life of the well to investigate and solve any production issues.

Uniform tracer distribution for accurate measurements

CARBONRT GP technology is a ceramic proppant that is manufactured with a proprietary tracer uniformly distributed throughout each proppant grain. The tracer is integral to the proppant matrix so it cannot be dissolved or washed away.

High quality evaluation anytime with standard tools

Our unique technology features an inert, permanently traceable material that has a high neutron capture cross-section. Analysis of the logs results in a direct measurement of where proppant is located, rather than an interpretation.

Unique evaluation technique and support services

CARBO has developed a proprietary method for evaluating gravel pack completions using our unique, field-proven tracer technology. The technique enables the direct measurement of the top of gravel and pack quality. Our team will also provide full support with the integration of CARBONRT GP technology into your gravel pack

All Product Files

Public access files

Benefits

Safe, Accurate, and Cost-Effective Gravel Pack Evaluation

Provides reliable assessments of gravel pack effectiveness in both cased-hole and open-hole completions, adaptable to horizontal or vertical well configurations, ensuring operational safety and cost-efficiency.

Detect Gravel Pack Coverage

Identifies the top of the gravel pack to ensure all productive zones are fully covered, allowing for optimal well performance.

Assess Proppant Pack Quality

Evaluates the quality and percent coverage of the proppant pack in the near-wellbore region, confirming effective material placement.

Identify Voids and Channels

Detects the presence of voids or channels in the gravel pack, which could lead to production impairment due to the ingress of fines or sand from the surrounding formation.

Features

An inert, permanent tracer that requires no special equipment, handling, permits, or licenses, making it both safe for operators and eco-friendly.

The tracer is uniformly distributed within each proppant grain—not merely coated—ensuring consistent performance. It can be incorporated into any CARBO ceramic proppant.

Easily detected using pulsed neutron logging tools running at standard speeds, ensuring seamless integration into existing well evaluation processes.

Frequently Asked Questions

1. What is CARBONRT® GP used for?

CARBONRT GP is designed for fracture evaluation by tracking proppant distribution within hydraulic fractures.

2. How does it benefit operators?

It allows precise real-time monitoring of fracture geometry to optimize well performance and improve operational decisions.

3. Is CARBONRT® GP compatible with standard equipment?

Yes, it works with gamma logging tools commonly used in the industry, requiring no additional infrastructure.

4. Is it environmentally safe?

CARBONRT GP is non-toxic and safe for use in various oilfield environments.

Get access

Please fill out the form to continue reading

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.

Get access

Please fill out the form to continue reading

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.

Join Us

Subscribe our newsletter and stay

up to date about the company

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.