Environmentally Friendly

This inert, permanent tracer is safe for the environment and requires no special equipment, handling, permits, or licenses to use.

CARBONRT inert tracer technology enables the high-definition evaluation of fractures in ceramic completed wells to help you optimize completion efficiency, production and field development. Our unique tracer technology enables the direct measurement of near-wellbore proppant location and quantity using our FRACTUREVISION proppant-delivered fracture evaluation service. The accurate measurements from the service allow the evaluation of perforation cluster efficiency and near-wellbore connectivity, which can be used to maximize estimated ultimate recovery (EUR). A precise understanding of proppant placement also supports the optimization of stage placement and proppant diversion.

Directly detect proppant location

The accurate measurements from the service allow the evaluation of perforation cluster efficiency and near-wellbore connectivity, which can be used to maximize estimated ultimate recovery (EUR). A precise understanding of proppant placement also supports the optimization of stage placement and proppant diversion.

Uniform tracer distribution for accurate measurements

CARBONRT technology is a proppant that is manufactured with a proprietary tracer uniformly distributed throughout each proppant grain. This assures consistent distribution of the tracer throughout the near-wellbore fracture zone, enabling more accurate measurement of proppant coverage and propped fracture height. As the tracer is integral to the proppant matrix it cannot be dissolved or washed away.

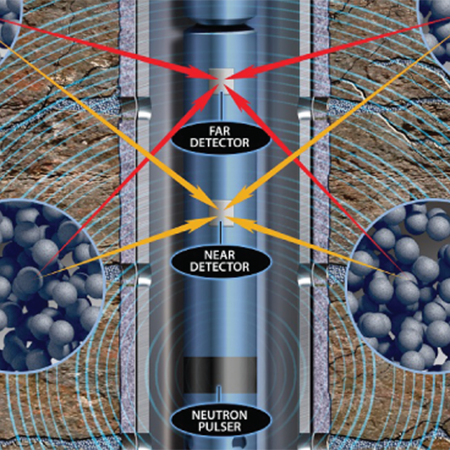

High quality measurements anytime with standard tools

Our unique technology features an inert traceable material that has a high neutron capture cross section which is detectable with a standard, cost-effective neutron logging tool run. This makes the result a direct measurement of where proppant is located, rather than an interpretation.

Detectable for the life of the well

With field-proven CARBONRT technology, there is no half-life deterioration of the detectable properties. Since the tracer is permanently identifiable, an operator has the flexibility of conducting post-fracture logging months or years after fracturing to quickly identify intervals for restimulation.

Operational and environmental advantages

Proppant enhanced with CARBONRT technology is pumped like any other and requires no special equipment, handling, training, permits or certifications. That delivers significant cost savings over other evaluation methods. The technology is also safer than particulate radioactive tracers, with no need for special handling considerations.

No impact on proppant performance or physical properties

The tracer is manufactured into the proppant matrix and represents less than 1% of the proppant chemistry, so the physical properties are almost identical and its downhole performance unaffected.

All Product Files

Get access

Please fill out the form to continue reading

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.

Benefits

1

Cost-Effective Fracture Evaluation in Vertical and Horizontal Ceramic-Completed Wells

This enables operators to assess well performance without the need for expensive or complex tools, leading to cost savings while maintaining high-quality data.

2

Proppant Coverage Identification

Provides valuable insight into the extent of fracture stimulation, ensuring that the proppant effectively reaches the target zones. This helps optimize well performance and ensures a more complete evaluation of fracture coverage.

3

Near-Wellbore Connectivity and Perforation Efficiency

Tracks the amount of proppant near the wellbore, offering critical data to evaluate the efficiency of perforations and how well fractures connect with the wellbore. This helps improve completion techniques for better flow and productivity.

4

Enhanced Fracture Simulation Models and Treatment Design

Enables precise measurements that feed into fracture simulation models, improving the accuracy of treatment designs and boosting overall completion efficiency. This leads to more effective resource extraction and reduces operational costs.

Features

This inert, permanent tracer is safe for the environment and requires no special equipment, handling, permits, or licenses to use.

Our advanced technology distributes evenly throughout each proppant grain and can be manufactured into any CARBO ceramic proppant.

CARBONRT utilizes pulsed nuetron logging tools run at standard speeds to provide accurate and precise results.

Case Studies

Resources

Frequently Asked Questions

1. What is CARBONRT® used for?

CARBONRT is designed for fracture evaluation by enabling precise tracking of proppant placement in hydraulic fracturing operations.

2. How does CARBONRT® improve well analysis?

Its built-in tracers allow operators to monitor fracture performance and optimize treatment strategies in real time.

3. Is CARBONRT® environmentally safe?

Yes, CARBONRT is non-toxic and integrates seamlessly into standard oilfield operations.

4. What tools are needed to monitor CARBONRT®?

It is compatible with standard gamma logging tools, eliminating the need for specialized equipment.

Get access

Please fill out the form to continue reading

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.

Get access

Please fill out the form to continue reading

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.

Join Us

Subscribe our newsletter and stay

up to date about the company

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.