CARBOGRIND XT is a high-performance, intermediate-density ceramic grinding media meticulously engineered to deliver exceptional performance and economic advantages in fine-grinding applications, specifically for soft minerals. With an emphasis on durability and precision, CARBOGRIND XT is designed to optimize the efficiency of grinding processes, reduce energy consumption, and lower operational costs, making it the ideal solution for industries seeking to maximize productivity.

The advanced sintering process employed in the manufacturing of CARBOGRIND XT ensures superior mechanical properties, including enhanced strength, exceptional wear resistance, and a longer operational life. This allows users to achieve better results with less media replenishment, minimizing downtime and maintenance costs.

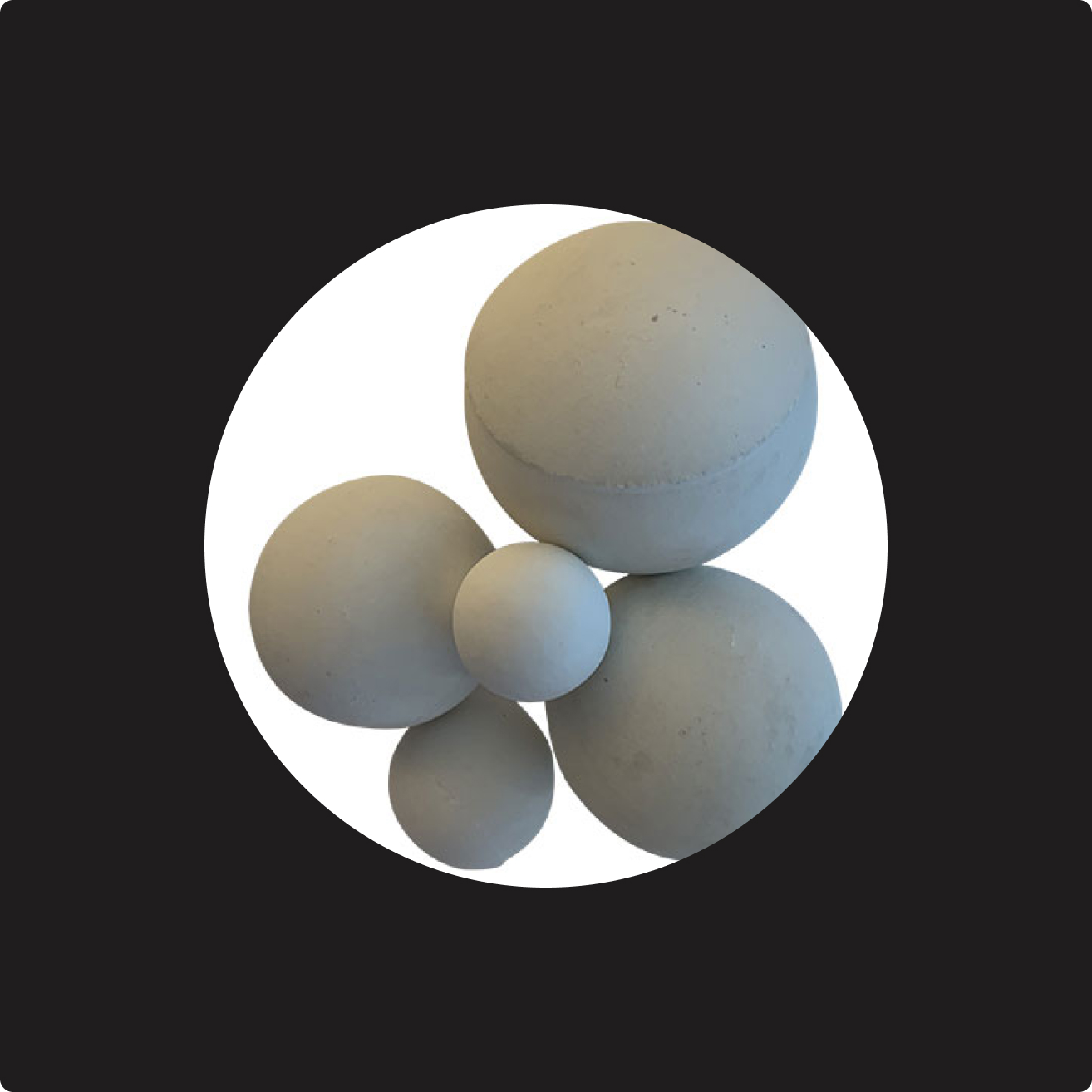

CARBOGRIND XT features consistent particle size and uniform shape, improving grinding performance and enhancing product uniformity. Its intermediate density ensures the perfect balance of grinding force and particle dispersion, which is particularly advantageous when processing softer mineral compositions, where traditional high-density media may cause overgrinding and unnecessary energy expenditure.

Whether in mining, mineral processing, or specialty industrial applications, CARBOGRIND XT provides a solution that aligns with sustainability goals by improving energy efficiency while maximizing throughput and minimizing waste.