High Mohs Hardness

Engineered with a high Mohs hardness, CARBOGRIND offers exceptional durability, extending the lifespan of milling media and reducing wear.

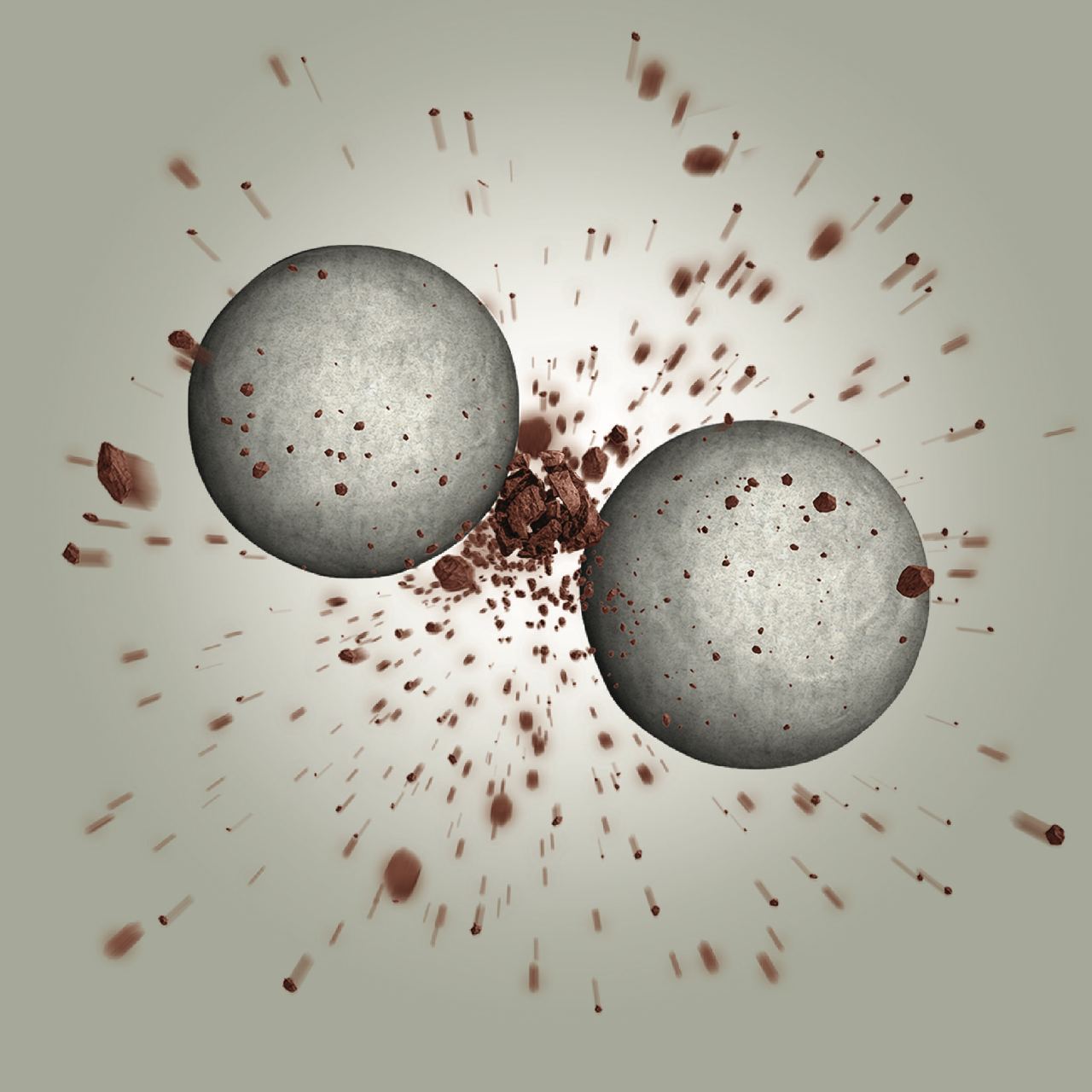

CARBOGRIND high-performance low-density ceramic grinding media is engineered to provide unmatched economic and performance advantages in fine grinding and ultra-fine grinding of soft and intermediate minerals in horizontal and vertical mills. Our sintering manufacturing process results in superior strength and wear resistance with a consistent particle size and shape.

All Product Files

Get access

Please fill out the form to continue reading

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.

Superior durability for longer product life

The sintering process used to manufacture CARBOGRIND yields a high Mohs hardness for greater durability and lower density. This translates into less equipment wear during milling, reduces final product contamination and lowers process costs. It extends the product life cycle, thus reducing media consumption and lowering the cost associated with transportation, disposal and replacement of materials.

Eliminates respirable silica dust exposure

Using CARBOGRIND reduces HSE concerns because it is chemically inert, non-hazardous and does not generate respirable silica dust.

Volume/cost advantages of lower density

Ideal for vertical milling

The unique chemical composition of CARBOGRIND produces the durability and density that make it ideal for use in vertical mill operations. It is engineered to optimize grinding efficiency in the mill, reducing input energy. The light-colored media yields the desired finish when light color and brightness of the final product are critical.

Improved grinding efficiency

CARBOGRIND is engineered for uniform particle size and shape. This reduces wear on mechanical parts of milling equipment, resulting in lower maintenance costs and less down time.

Benefits

Better Value and Performance

CARBOGRIND ceramic media is engineered to deliver superior value compared to steel balls and lower-quality alumina-based alternatives, offering higher efficiency and performance in various applications.

Superior Durability

The robust design reduces wear and tear on equipment, minimizes media consumption, and lowers long-term operational costs, making it a cost-effective choice.

Reduced Product Contamination

Its high-quality composition minimizes contamination in the final product, ensuring a purer outcome for precision applications.

Lower Process and Maintenance Costs

By decreasing media consumption and reducing the need for frequent equipment maintenance, CARBOGRIND helps cut overall process and maintenance expenses.

Features

Engineered with a high Mohs hardness, CARBOGRIND offers exceptional durability, extending the lifespan of milling media and reducing wear.

CARBOGRIND eliminates the exposure to respirable silica dust, promoting a safer working environment and compliance with health regulations.

Its design makes CARBOGRIND ideal for vertical milling applications, enhancing efficiency and performance in various industrial processes.

Case Studies

Resources

Frequently Asked Questions

1. What is CARBOGRIND® used for?

CARBOGRIND is designed for fine grinding applications, providing high performance for industries processing soft minerals and other materials.

2. How does it improve grinding efficiency?

Its uniform size and shape ensure even particle dispersion, maximizing grinding efficiency and reducing energy consumption.

3. Is CARBOGRIND durable?

Yes, it is engineered with high wear resistance, extending its operational life and minimizing media replacement.

4. What industries benefit from CARBOGRIND?

It is ideal for mineral processing, mining, and specialty chemical applications requiring consistent grinding performance.

5. Is it environmentally safe?

Yes, CARBOGRIND is chemically inert, ensuring it is safe to use and handle

6. How does it compare to traditional grinding media?

CARBOGRIND offers superior durability and cost-efficiency compared to traditional materials like steel or sand.

Get access

Please fill out the form to continue reading

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.

Get access

Please fill out the form to continue reading

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.

Join Us

Subscribe our newsletter and stay

up to date about the company

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.