CARBOBOND KRYPTOSPHERE LD

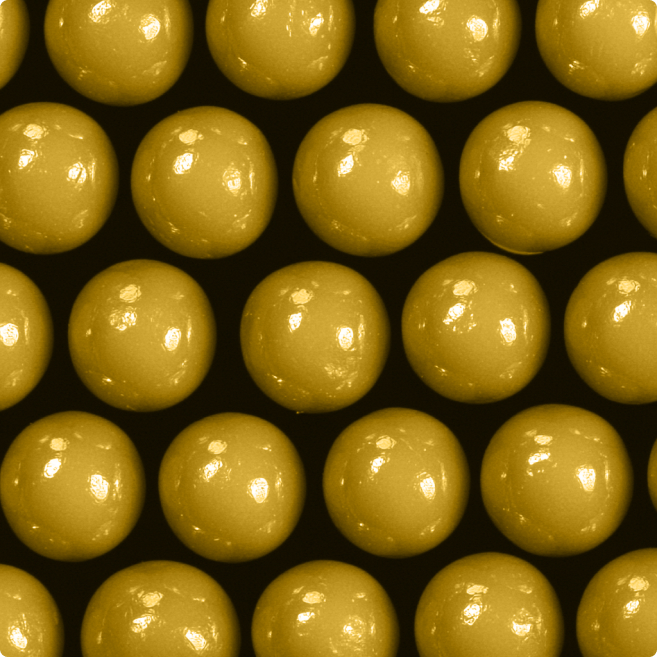

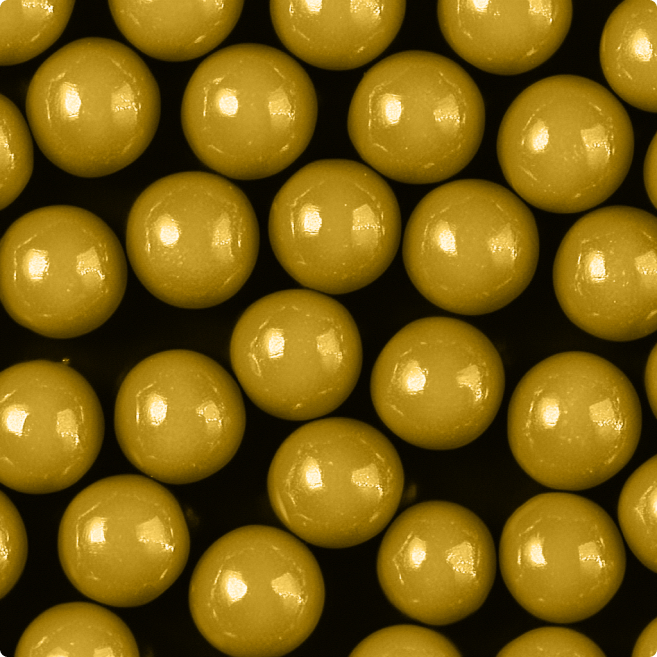

The higher-strength CARBOBOND KRYPTOSPHERE LD resin-coated low-density, ultra high-performance ceramic proppant is effective at greater well depths, temperatures and stresses than any comparable ceramic proppant. CARBOBOND KRYPTOSPHERE LD also requires 20% less proppant by weight than any resin-coated intermediate-density ceramic proppant and 30% less proppant than any resin-coated bauxite ceramic proppant. It is designed with high cyclic loading tolerance, and the bonded proppant pack reduces the effective stresses encountered at deeper depths.

All Product Files

Get access

Please fill out the form to continue reading

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.

Benefits

Why Choose

CARBOBOND KRYPTOSPHERE LD

-

Versatile—expands the usable application range (depth, temperature and stress) to replace intermediate-density and bauxite

-

No proppant flowback—eliminates subsequent equipment damage, expense of cleanouts and disposal

-

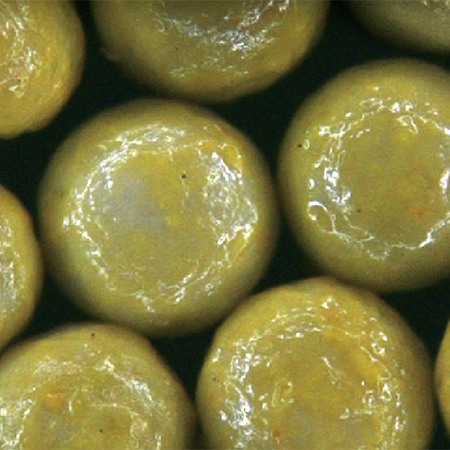

Maintains conductivity—resin coating prevents fines from being released

-

Maintains particle integrity—prevents chemical attack on substrate

-

No additional chemical costs—since no fluid chemistry change is required, the job can be pumped as designed

Features

Advanced Attributes

of CARBOBOND KRYPTOSPHERE LD

-

KRYPTOSPHERE LD provides an ultraconductive, low-density proppant as the substrate

-

Specially formulated for maximum compatibility with complicated frac fluids used in deeper wells

-

Bonded proppant pack reduces effective stress on proppant

-

High cyclic loading tolerance

-

Resin coating completely encapsulates substrate

-

Bonds in the fracture with temperature and closure

Resources

Comprehensive

Knowledge Hub

Frequently Asked Questions

Learn more about

CARBOBOND KRYPTOSPHERE LD

-

1. What is CARBOBOND KRYPTOSPHERE LD used for?

It is a resin-coated, lightweight ceramic proppant designed to maintain fracture conductivity and prevent proppant flowback in low-pressure reservoirs.

-

2. How does the resin coating improve performance?

The resin coating bonds proppant grains, stabilizing the pack to reduce flowback and maintain well integrity.

-

3. What type of wells benefit from this product?

It is ideal for low-pressure and unconsolidated reservoirs, where stable, lightweight proppants are needed.

-

4. How does it enhance operational efficiency?

Its lightweight design and flowback control reduce downtime, improving well productivity and lowering maintenance costs.

-

5. Is it environmentally safe?

Yes, it is chemically inert and safe for long-term use.

-

6. Can it be used with various fracturing fluids?

Yes, it is compatible with multiple fluid systems, providing flexibility in operations.

-

7. How does it compare to other proppants?

It offers higher stability and conductivity than traditional sand or uncoated ceramics.

Get access

Please fill out the form to continue reading

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.

Get access

Please fill out the form to continue reading

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.

Join Us

Subscribe our newsletter and stay

up to date about the company

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.