Uniform Size and Shape

Ensures consistent performance in casting processes.

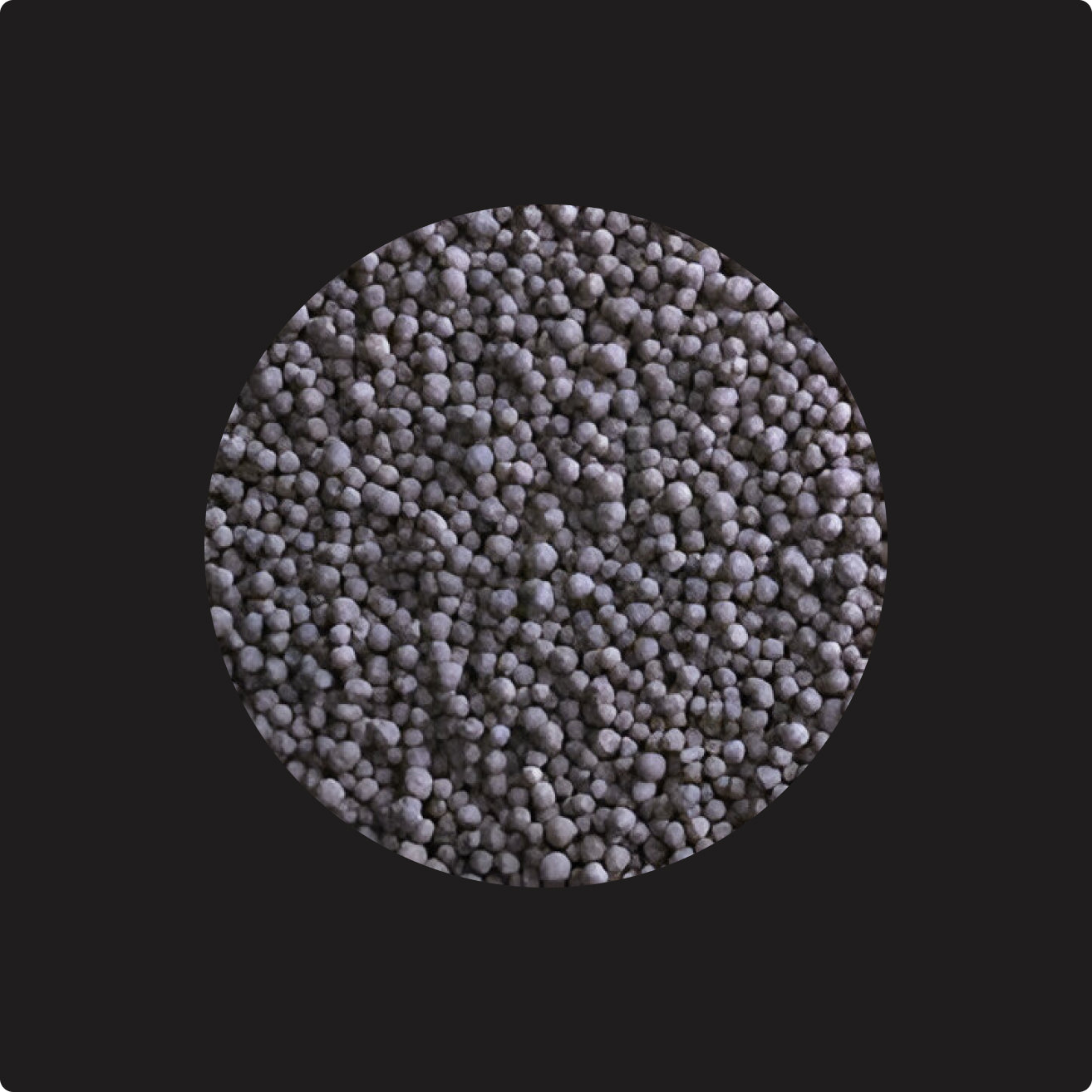

ACCUCAST LD ceramic sand casting media is a low-density, high-performance solution designed for metal casting applications, providing a unique combination of consistent thermal, physical, and chemical properties. Its exceptional formulation outperforms traditional sand products, offering significant economic advantages and enhanced performance. Engineered for optimal strength and stability, ACCUCAST minimizes defects during the casting process, leading to improved dimensional accuracy and efficiency. This innovative media not only supports higher production rates but also contributes to a safer and more sustainable foundry environment.

All Product Files

Get access

Please fill out the form to continue reading

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.

Benefits

Enhanced Dimensional Accuracy

Achieves greater precision in castings, leading to improved fit and functionality.

Reduced Defects

Minimizes imperfections during the casting process, resulting in higher-quality output.

Accelerated Production Cycle Times

Facilitates quicker manufacturing processes, increasing overall productivity.

Lower Scrap and Cleaning Requirements

Decreases waste and reduces the time needed for post-casting cleaning, improving efficiency.

Decreased Media and Energy Costs

Lowers consumption of materials and energy, translating to cost savings and enhanced sustainability.

Improved QHSE Standards

Supports better quality, health, safety, and environmental practices in the foundry.

Features

Ensures consistent performance in casting processes.

Spherical structure enhances flowability and packing density.

Provides long-lasting performance in demanding applications.

Non-hazardous and does not produce respirable silica dust, promoting safety.

Case Studies

Resources

Frequently Asked Questions

1. What is ACCUCAST LD used for?

ACCUCAST LD is designed for lightweight casting applications, offering reliable performance for producing complex metal parts.

2. How does it reduce casting defects?

Its low thermal expansion minimizes penetration and veining defects, improving casting precision and quality.

3. Is ACCUCAST LD reusable?

Yes, the media is reusable, making it cost-effective and environmentally sustainable.

4. What industries benefit from ACCUCAST LD?

It is ideal for automotive, aerospace, and industrial foundries requiring lightweight, precision castings.

Get access

Please fill out the form to continue reading

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.

Get access

Please fill out the form to continue reading

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.

Join Us

Subscribe our newsletter and stay

up to date about the company

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.