Revolutionizing Shell Building Efficiency

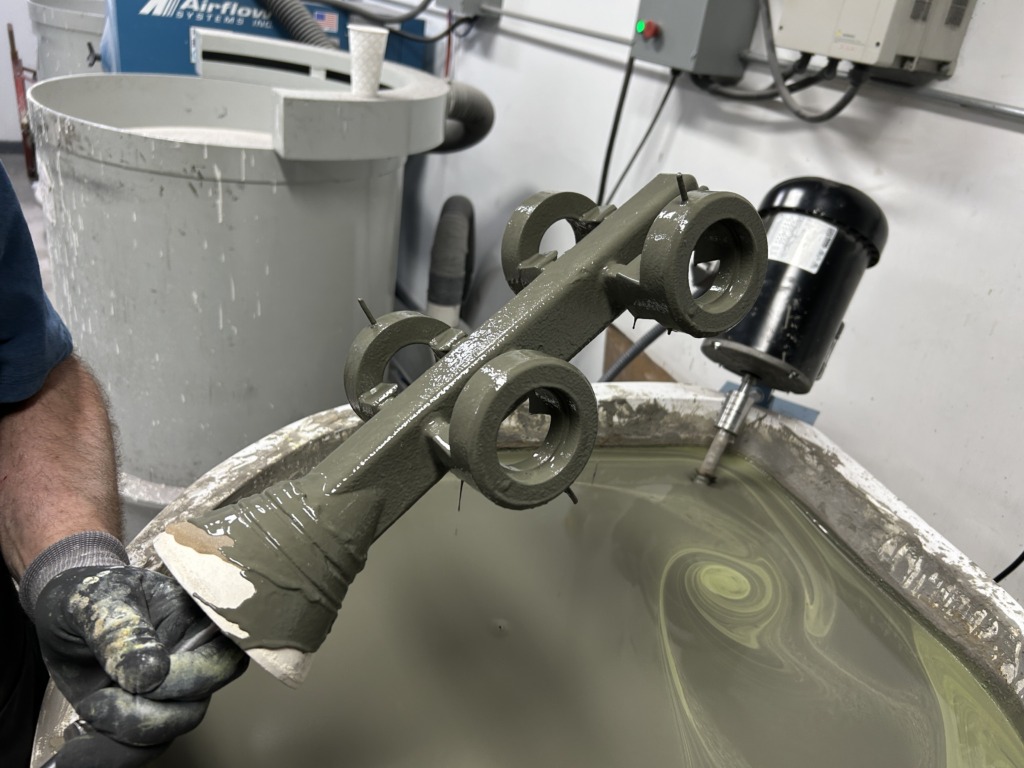

A major investment casting foundry recently achieved a significant process improvement by replacing zircon flour and stucco sands with OPTICAST, CARBO’s advanced ceramic casting media. This transition allowed the foundry to streamline its shell building sequence from a traditional 2-1-4 to a 1-1-4 sequence, eliminating a full dip while maintaining exceptional casting quality.

This breakthrough delivers time and cost savings while showcasing the performance advantages of OPTICAST as a high-performing, Made-in-the-USA zircon alternative for precision casting and lost wax casting operations.

Fewer Dips. Faster Production. Greater ROI.

In investment casting, also known as lost wax casting or precision casting, every dip layer adds time, material, and energy costs. Reducing even a single dip can significantly enhance throughput and efficiency, especially in these applications where consistency is critical.

By switching to OPTICAST, this foundry realized:

- Shorter cycle times – reducing drying and handling requirements

- Lower material consumption – less slurry and refractory needed

- Improved productivity – higher mold output with no equipment changes

- Cost savings – reduced labor, energy, and process time

This shift enables foundries to optimize shell building without sacrificing performance — an outcome that’s rarely achievable with traditional zircon-based systems.

Why OPTICAST Outperforms Zircon

OPTICAST is engineered from refined aluminum oxide, offering 72–80% refractory content and non-reactive consistency. In contrast, zircon, sourced from natural mines, often contains impurities and variable quality, leading to inconsistencies in shell performance.

The result:

- Higher temperature capabilities and chemical stability

- Controlled particle size and consistent shell structure

- Improved permeability and surface finish

- Reliable supply chain and stable pricing

These properties allow foundries to build stronger, more predictable molds with fewer dips, driving operational excellence and casting precision.

Reliable. Consistent. Made in the USA.

Unlike zircon, which faces global supply chain volatility, OPTICAST is manufactured domestically. CARBO’s U.S.-based production ensures:

- Reliable availability

- Consistent quality

- Predictable pricing

This stability empowers foundries to plan confidently, avoid material disruptions, and maintain steady output, all while meeting the stringent performance standards of precision casting applications.

Proven Performance in Foundry Trials

Across multiple foundry trials, OPTICAST has consistently demonstrated:

- Improved shell uniformity and dimensional accuracy

- Enhanced mold strength under thermal stress

- Zero reactivity issues or shell defects

These results validate OPTICAST as a next-generation casting media that enables dip sequence optimization and process simplification for investment casting foundries worldwide.

A Smarter Path Forward

This success story proves that OPTICAST isn’t just a replacement. It’s an upgrade. With fewer dips, faster cycle times, and superior shell performance, OPTICAST is redefining the standard for efficiency and reliability in investment casting.

As foundries face growing pressure to control costs and streamline operations, OPTICAST delivers the innovation, consistency, and U.S.-based supply stability they need to stay competitive.