In the dynamic world of hydraulic fracturing and oil extraction, CARBO’s innovative introduction of NANOMITE Express stands as a game-changer. This advancement in microproppant technology demonstrates CARBO’s commitment to improving operational efficiencies, enhancing safety, and driving cost-effective solutions in the energy sector.

NANOMITE Express: Bridging Efficiency and Simplicity

NANOMITE Express is the pelletized form of CARBO’s high-strength ceramic microproppant, NANOMITE. Designed with operational ease in mind, it simplifies transport and handling by allowing the microproppant to be delivered and deployed as a traditional proppant. Unlike conventional slurried microproppants, this product eliminates the need for complex slurrying processes, reducing both cost and logistical challenges.

The pelletized format enables seamless integration into existing operational frameworks, utilizing standard equipment for deployment. The result is a reduction in health, safety, and environmental risks, as the silica-free composition of NANOMITE Express minimizes dust exposure, a major concern in field operations

Transport and Safety: The Core Benefits

One of the standout features of NANOMITE Express is its superior transport efficiency. With a wide particle size distribution and extremely low settling velocity, this microproppant travels deeper into fracture networks, ensuring comprehensive coverage and proppant placement. It boasts an average settling rate 11 times slower than traditional 100-mesh sand, enhancing its efficacy even in low-viscosity fluids like freshwater or slickwater.

In terms of safety, the product’s pelletized nature significantly reduces health hazards associated with dust generation, a prevalent issue in traditional proppant handling. This innovation not only protects workers but also aligns with stricter environmental and health safety standards.

Proven Success: Anticipated Results Backed by Case Histories

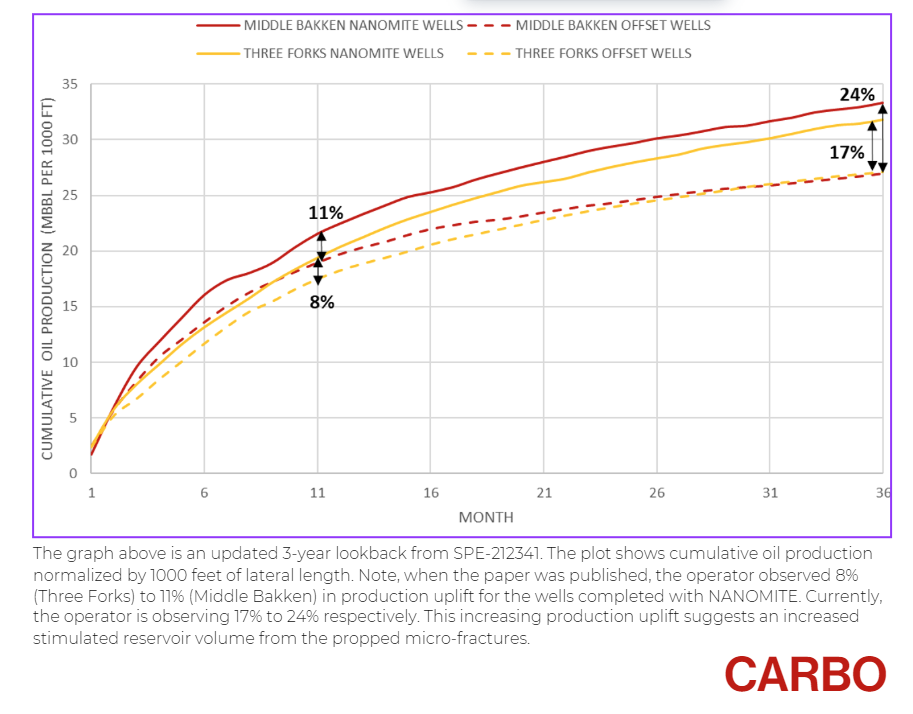

NANOMITE Express’ design builds on the proven success of CARBO’s NANOMITE microproppant, which has been validated across multiple formations through published studies like SPE-212341. Field trials with NANOMITE in the Bakken formation demonstrated significant production uplifts, with cumulative oil production increases ranging from 17% to 24% in various formations.

NANOMITE Express shares the same performance-enhancing benefits as NANOMITE, including deeper penetration into fracture networks, more uniform proppant distribution, and enhanced reservoir stimulation. What sets NANOMITE Express apart is its pelletized form, which simplifies transport and handling without compromising these proven operational efficiencies. This innovation enables operators to achieve the same impactful results with greater ease and cost-effectiveness, making it a powerful tool for boosting recovery rates and sustaining production.

The CARBO Edge: Innovation Meets Practicality

CARBO’s NANOMITE Express exemplifies the perfect blend of innovation and practicality. By reimagining how microproppants are transported, delivered, and utilized, CARBO addresses critical industry challenges, including cost efficiency, environmental responsibility, and operational safety. This product sets a new benchmark for the industry, offering a compelling solution for operators seeking to maximize efficiency and productivity while adhering to stringent health and safety standards.

As CARBO continues to push the boundaries of proppant technology, NANOMITE Express remains a shining example of the company’s dedication to advancing the energy sector through innovation, safety, and sustainability.

Thank you for completing the form!

We appreciate your interest and look forward to providing you with valuable content.