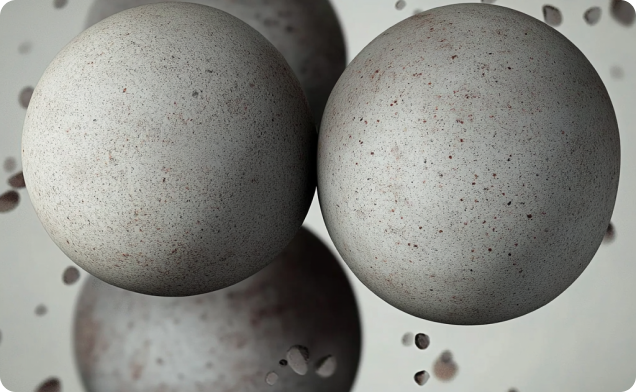

CARBOGRIND

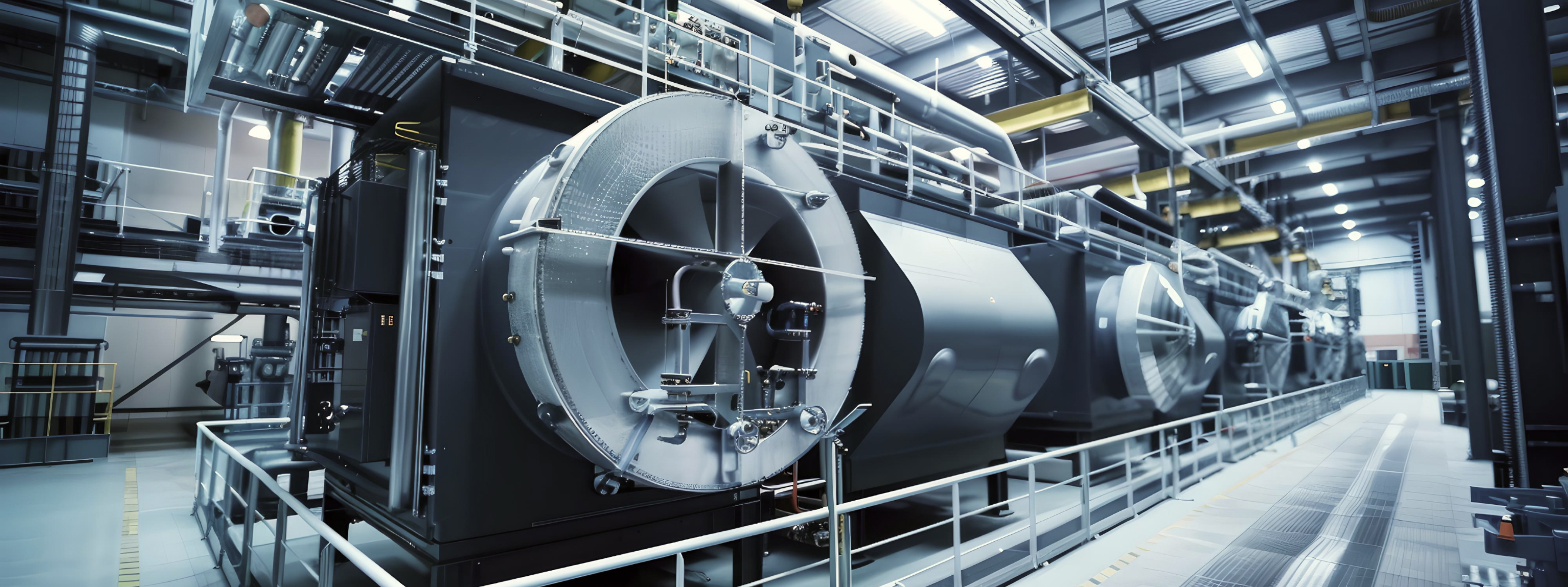

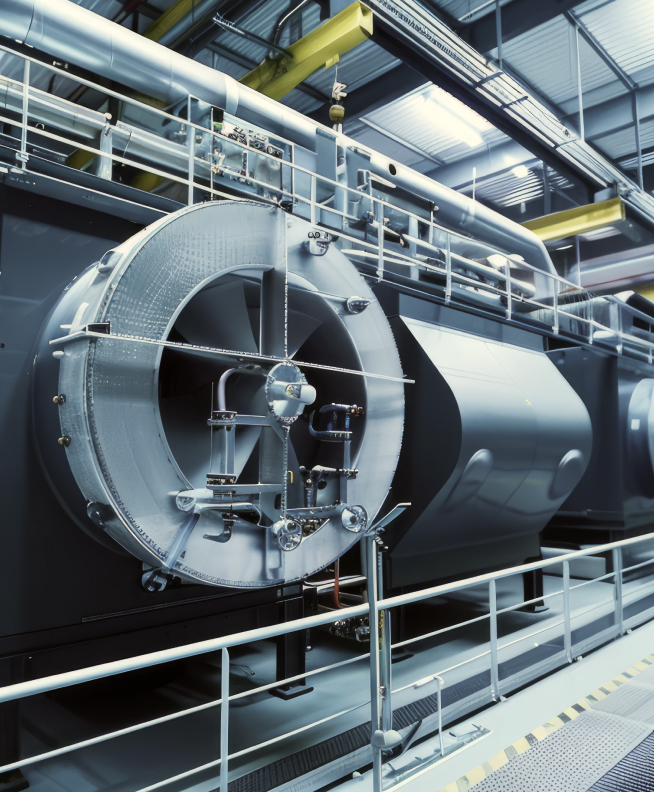

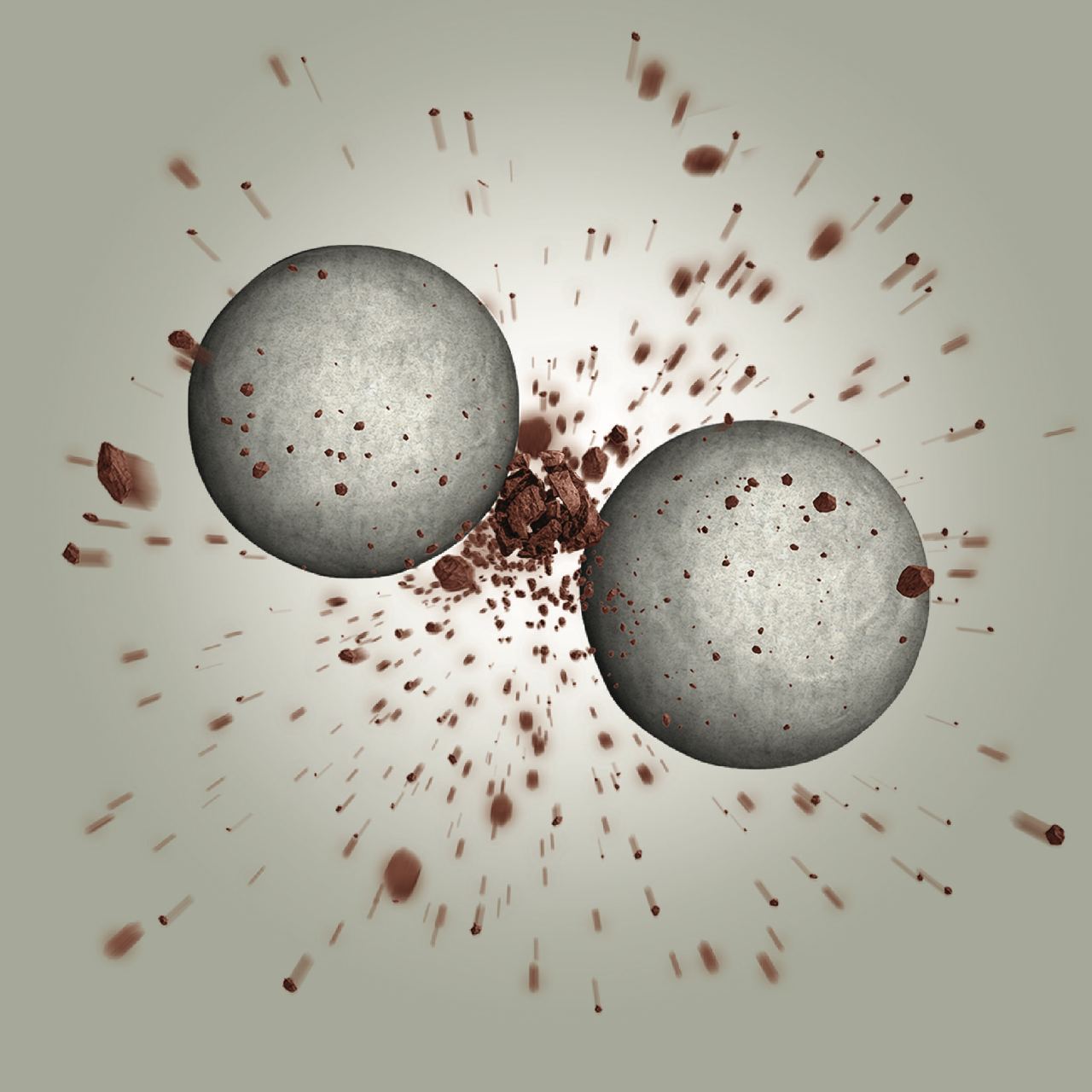

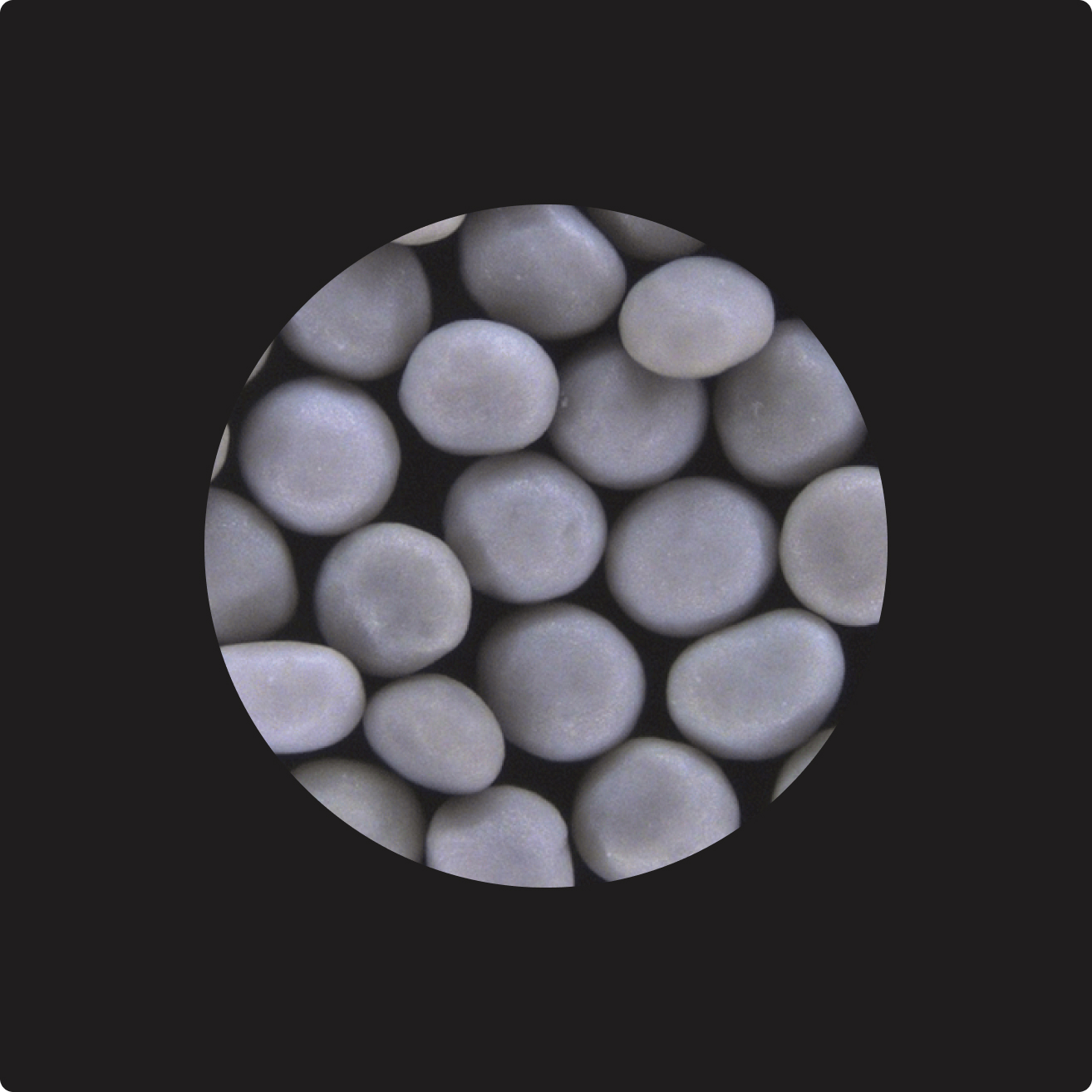

CARBOGRIND high-performance low-density ceramic grinding media is engineered to provide unmatched economic and performance advantages in fine grinding and ultra-fine grinding of soft and intermediate minerals in horizontal and vertical mills. Our sintering manufacturing process results in superior strength and wear resistance with a consistent particle size and shape.