KRYPTOSPHERE LD

The higher-strength CARBOBOND KRYPTOSPHERE LD resin-coated low-density, ultra high-performance ceramic proppant is effective at greater well depths, temperatures and stresses than any comparable ceramic proppant.

Ultra-conductive proppant technologies are engineered to deliver superior

conductivity, enhancing hydrocarbon flow and maximizing well productivity.

Whether operating in conventional reservoirs or challenging deepwater conditions, CARBO’s ultra-conductive proppants provide unmatched durability and performance, allowing operators to achieve greater production efficiency and reservoir recovery. Explore how our innovations in proppant technology can transform your well completions for sustained success.

In this video, Terry Palisch from CARBO Ceramics interviews David Norman, who played a key role in developing CARBO’s Kryptosphere proppant technology. David discusses his challenges while working on high-stress offshore and deepwater projects and how standard materials failed to maintain conductivity under cyclic stress. This led him to collaborate with CARBO to create a more durable, proppant solution.

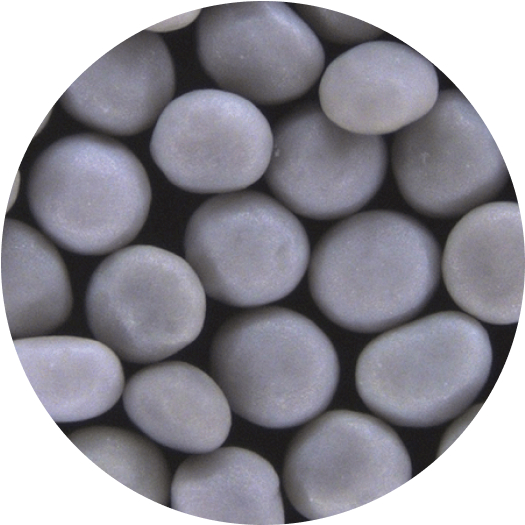

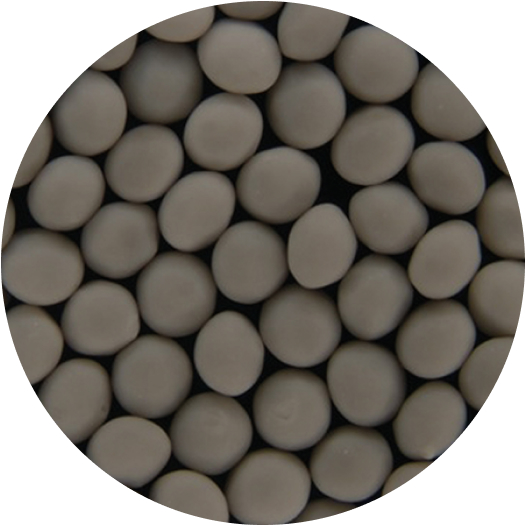

David explains how the Kryptosphere technology was developed to address issues like proppant degradation, fracture conductivity, and cycling stresses, especially in the Gulf of Mexico’s high-pressure environments. He highlights key attributes of Kryptosphere, such as its spherical shape, lack of internal flaws, and uniform mesh size, which contribute to better performance and longer well life.

The video provides valuable insights into the technology’s real-world applications, including improved proppant transport and longevity, making it a vital tool for operators looking to maximize healthy productivity and efficiency.

Our products

KRYPTOSPHERE LD

The higher-strength CARBOBOND KRYPTOSPHERE LD resin-coated low-density, ultra high-performance ceramic proppant is effective at greater well depths, temperatures and stresses than any comparable ceramic proppant.

KRYPTOSPHERE XT

CARBOBOND® KRYPTOSPHERE® XT resin-coated, ultra high-performance ceramic proppant is effective at greater well depths, temperatures and stresses than any comparable ceramic proppant. CARBOBOND KRYPTOSPHERE XT also requires 20% less proppant by weight than any resin-coated intermediate-density ceramic proppant and 30% less proppant than any resin-coated bauxite ceramic proppant.

KRYPTOSPHERE HD

CARBOBOND KRYPTOSPHERE® HD is an ultra-conductive, high density ceramic proppant technology, specifically engineered for high closure stress and risk environments, including ultra-deepwater regions such as the Gulf of Mexico.

Explore CARBO’s comprehensive range of advanced

products designed specifically for the mining industry.

Resources

Products & Services

ACCUCAST HT ceramic sand media is engineered to deliver exceptional performance through its unique combination of thermal, physical, and chemical properties.

High-transport, low-density, low-crush ceramic proppant

CARBOISP LITE is an innovative proppant technology that combines the characteristics of an intermediate-strength proppant with all the advantages of lightweight ceramics, providing optimum fracture conductivity and proppant transport.

CARBOTRACE Production surveillance integrated with CARBO quality proppants. Deployed with any type and size of proppant, CARBOTRACE offers a quantitative analysis of the fraction contribution of the oil, water and gas phases for each frac stage.

Frequently Asked Questions

What are CARBO Ultra-Conductive proppants and what are their characteristics?

The KRYPTOSPHERE platform of proppants constitute CARBO’s offering of Ultra-Conductive Proppants. They are made with a novel pelletizing process that imparts 3 unique characteristics: a single mesh sieve distribution, highly round and spherical pellets and fully densified pellets with minimal internal porosity. These characteristics result in Ultra-Conductive proppants, exceeding the performance of any other proppant in the market.

What are the products within the KRYPTOSPHERE platform and what is their application envelope?

There are 4 (four) products within the KRYPTOSPHERE platform.

KRYPTOSPHERE LD: it is a lightweight proppant made with kaolin ores applying the KRYPTOSPHERE pelletizing process. It exceeds the conductivity performance of ISP and HSP. Its 2.8 lightweight ASG gives it a 15 to 25% volume advantage vs ISP and HSP, which reduces the proppant requirement and associated cost by that same percentage for a frac of fixed dimensions. Its application envelope extends up to 12,000 psi stress on proppants.

KRYPTOSPHERE HD: it is a high density lightweight proppant made with bauxite ores that achieved the highest strength and conductivity in the industry. Its range of application extends to the deepest and highest stressed formations exceeding 20,000 psi stress on proppant.

KRYPTOSPHERE XT: is an extension of the LD version with enhanced properties to extend its application to higher stressed formations. Also made to an ASG of 2.8 it is applied in the range from 12,000 to 15,000 psi to fill the gap between the KRYPTOSPHERE LD and HD versions.

KRYPTOAIR is the ultra lightweight product in the family. With an ASG as low as 1.6 it is made to prioritize placement for horizontal well gravel packing where proppant transport is critical.

What are the KRYPTOSPHERE proppant mesh sizes available and their equivalent standard mesh sizes?

KRYPTOSPHERE proppants are manufactured in single mesh, in a size equivalent to the mean diameter standard sizes. The available sizes and equivalencies are listed below:

| KRYPTOSPHERE single mesh size | Equivalent Standard mesh size |

| 18 | 16/20 |

| 20 | 16/30 |

| 25 | 20/40 |

| 35 | 30/50 |

| 45 | 40/70 |

What are the sand retention characteristics of KRYPTOSPHERE proppants applied to a sand control environment in a gravel pack or fracpack completion?

Sand retention testing was conducted at Constien & Associates for KRYPTOSPHERE 25 and 35 proppants and compared to their equivalent 20/40 and 30/50 standard sizes. Results show the same sand retention properties for 25 compared to 20/40 and 35 compared to 30/50 sizes. This suggests the same results can be expected and extended to the rest of single to standard mesh equivalent sizes. The referred testing and results are published in paper SPE-196139.

Should I use KRYPTOSPHERE ultra conductive proppants, why?

The decision of using KRYPTOSPHERE, or any other proppant for the matter, is an economics exercise. The process involves assessing the effective conductivity of KRYPTOSPHERE vs. the various proppant options at the reservoir conditions it will operate at, estimate the frac and well production profile with the resulting conductivity and assessing the cost-benefit of each option with an economic indicator, typically NPV or ROI. The proppant with the higher NPV or ROI is the one that will generate the most economic value and should be selected. CARBO can assist with this process as part of our service.

Get access

Please fill out the form to continue reading

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.

Get access

Please fill out the form to continue reading

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.

Join Us

Subscribe our newsletter and stay

up to date about the company

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.