CARBOBOND LITE

The higher-strength CARBOBOND LITE resin-coated low-density, high-performance ceramic proppant is effective at greater well depths, temperatures and stresses than any comparable premium lightweight ceramic proppant.

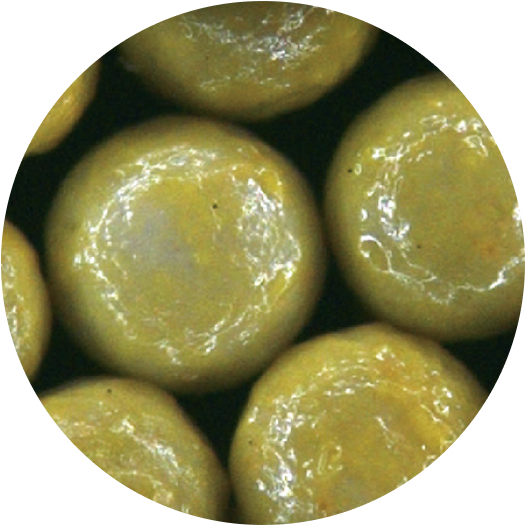

Avoid proppant pack washouts, voids, and loss of wells with CARBO’s

proppant pack consolidation technology.

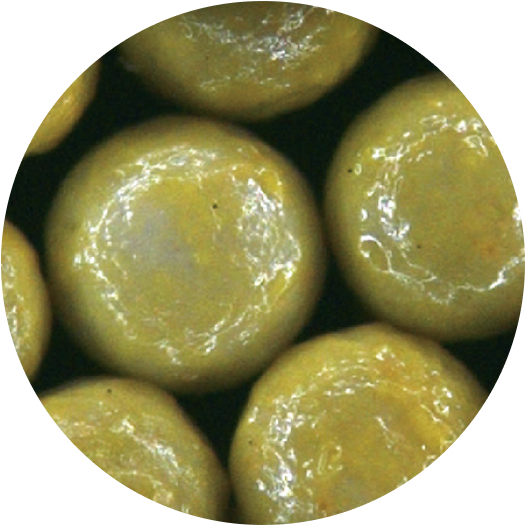

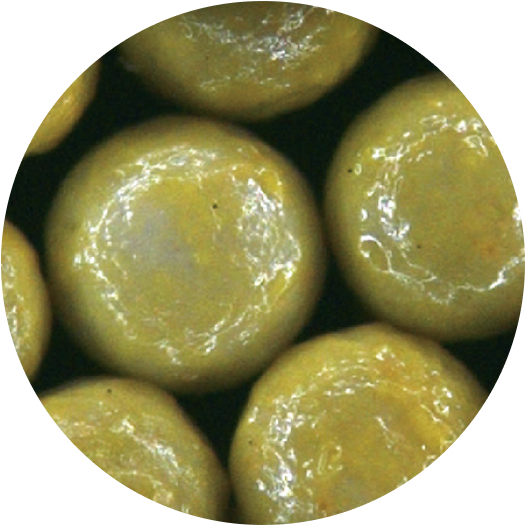

With a resin coating that fully encapsulates the substrate, it resists cyclic loading and bonds in the fracture under temperature and closure. Benefits include versatility across various conditions, prevention of proppant flowback (reducing equipment damage and cleanout costs), maintenance of conductivity by preventing fines, and protection of particle integrity. No additional chemicals are needed, allowing the job to be pumped as designed.

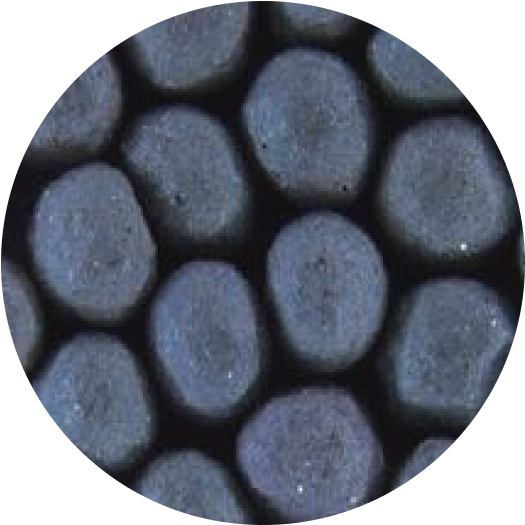

FUSION proppant pack consolidation technology enables the creation of a bonded, high-integrity proppant pack without the need for closure stress, revolutionizing well performance. This cutting-edge technology enhances well integrity, allowing operators to inject and produce at the ultra-high flow rates necessary to maximize efficiency. By improving the structural stability of the proppant pack, FUSION technology helps to minimize production losses and reduce operational risks. This leads to better well economics, increasing the ultimate recovery (EUR) and extending the productive life of the well, making it a vital solution for high-performance wells.

Watch CARBO’s FUSION proppant pack consolidation technology at work. With FUSION, you can now create a bonded, high integrity proppant pack without closure stress. Providing well integrity critical to inject and produce at ultra-high rates required to improve well economics and increase EUR.

Our products

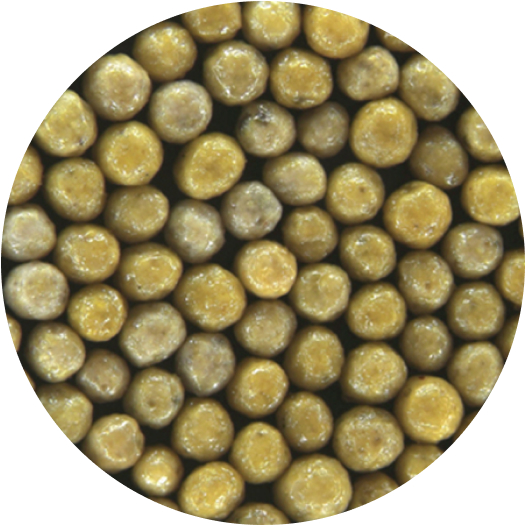

CARBOBOND LITE

The higher-strength CARBOBOND LITE resin-coated low-density, high-performance ceramic proppant is effective at greater well depths, temperatures and stresses than any comparable premium lightweight ceramic proppant.

CARBOBOND CARBOPROP

CARBOLITE high-performance, low-density ceramic proppant technology has a bulk density and specific gravity similar to sand, yet delivers higher conductivity and flow capacity to enhance production and your estimated ultimate recovery (EUR).

CARBOBOND CARBOHSP

High-transport, low-density, low-crush ceramic proppant.

CARBOISP LITE is an innovative proppant technology that combines the characteristics of an intermediate-strength proppant with all the advantages of lightweight ceramics, providing optimum fracture conductivity and proppant transport.

CARBOBOND KRYPTOSPHERE LD

The higher-strength CARBOBOND KRYPTOSPHERE LD resin-coated low-density, ultra high-performance ceramic proppant is effective at greater well depths, temperatures and stresses than any comparable ceramic proppant.

CARBOBOND KRYPTOSPHERE XT

CARBOBOND® KRYPTOSPHERE® XT resin-coated, ultra high-performance ceramic proppant is effective at greater well depths, temperatures and stresses than any comparable ceramic proppant. CARBOBOND KRYPTOSPHERE XT also requires 20% less proppant by weight than any resin-coated intermediate-density ceramic proppant and 30% less proppant than any resin-coated bauxite ceramic proppant.

CARBOBOND KRYPTOSPHERE HD

CARBOBOND KRYPTOSPHERE® HD is an ultra-conductive, high density ceramic proppant technology, specifically engineered for high closure stress and risk environments, including ultra-deepwater regions such as the Gulf of Mexico.

FUSION

With FUSION proppant pack consolidation technology you can now create a bonded, high integrity proppant pack with or without closure stress.

ARTICBOND

ARCTICBOND is a resin-coated sand proppant, designed for effective flowback control in low-stress, low-temperature environments.

Explore CARBO’s comprehensive range of advanced

products designed specifically for the mining industry.

Resources

Products & Services

ACCUCAST HT ceramic sand media is engineered to deliver exceptional performance through its unique combination of thermal, physical, and chemical properties.

High-transport, low-density, low-crush ceramic proppant

CARBOISP LITE is an innovative proppant technology that combines the characteristics of an intermediate-strength proppant with all the advantages of lightweight ceramics, providing optimum fracture conductivity and proppant transport.

CARBOTRACE Production surveillance integrated with CARBO quality proppants. Deployed with any type and size of proppant, CARBOTRACE offers a quantitative analysis of the fraction contribution of the oil, water and gas phases for each frac stage.

Frequently Asked Questions

What are CARBO Proppant Pack Consolidation Technologies?

CARBO offers a number of technologies to maintain the proppant pack integrity in hydraulic frac, gravel pack and fracpack applications to prevent proppant flowback and completion failure. They apply both to initial completion and remedial applications. These include CARBOBOND, FUSION and ARCTICBOND technologies.

What is CARBOBOND?

CARBOBOND is the family name for the unique curable resin coatings developed by CARBO. It is applied to any CARBO ceramic proppants or natural sand to prevent flowback and maintain pack integrity. CARBOBOND is designed to cure only under stress in the frac, underushed proppants left in the casing or frac string will not bond enabling simple flowback and cleanout.

What is FUSION? What is ARCTICBOND?

FUSION and ARCTICBOND technologies features a proprietary resin coating and unique chemical-activator that react downhole to form a consolidated proppant pack. The chemical-activated bonding process forms a strong, flexible bond with or without compression stress applied even in low temperature environments to create a high integrity pack that withstands stress cycling to sustain long-term pack integrity. The unique characteristics of FUSION and ARCTICBOND are their ability to work in a wide range of temperature from ambient to 600°F, stress range from zero to any stress, and high shear conditions in power injector and high production wells.

FUSION and ARCTICBOND feature the same coating and activator technology applied to a ceramic or natural substrate respectively. They present alternatives for operating environments trading off the conductivity and strength of ceramics vs. lower cost of sand.

What is the temperature range of application for CARBOBOND?

CARBOBOND can be applied from 120°F up to 600°F. For temperatures below 160°F a Low Temperature Chemical Activator is required to enhance the bonding process. Below 120°F FUSION or ARCTICBOND are recommended.

What is the temperature range of application for FUSION and ARCTICBOND?

FUSION and ARCTICBOND can be applied from ambient temperature (~70°) to 600°F.

What fluids have been used with CARBOBOND, FUSION and ARCTICBOND? Are there any fluid compatibility issues I should be aware of?

CARBOBOND, FUSION and ARCTICBOND have been pumped with a wide variety of fluids ranging from brines, friction reducer (FR) and linear gels to complex x-linked fluid systems comprising borate, HT delayed borate, HT delayed Zirconate and HT dual Borate-Zirconate fluid systems from diverse major, regional and local service companies. While CARBOBOND, FUSION and ARCTICBOND have not posed fluid compatibility issues they are curable resin systems that may interact with and may need minor x-linkers and breaker adjustments. Fluid stability testing is advised for this purpose.

How is resin coated material properly pneumatically transferred in the field?

The material should be gravity fed or pneumatically transferred @ 5-8 psi to avoid damaging the coating, just the same as any other proppant. Resin coated prop is an electrical insulator so we also ground the delivery truck to the field bin to help avoid static charge build up.

What is the shelf life of CARBOBOND, FUSION and ARCTICBOND curable resin coated products and Activators?

If stored properly (cool & dry) the shelf life is greater than 3 years. If in doubt samples should be collected and sent to CARBO for testing and recertification of proper performance of the product.

Will underflushed CARBOBOND, FUSION and ARCTICBOND consolidate in the wellbore, if so, how can it be removed?

While CARBOBOND is designed not to consolidate inside causing the absence of stress, FUSION and ARCTICBOND will. FUSION and ARCTICBOND are designed to provide several hours of working time based on BHT at the end of pumping and activator concentration. This working time can be used to clean out proppants from casing in the event of a premature screenout. On occasion, particularly if cleanout operations exceed the working time, these proppant systems may consolidate in the wellbore and require drill out or chemical removal. For drilling operations a stair-step, insert bit or 4 blade bit is recommended. Type of bit will quickly break up the consolidated proppant. It should be the “toothiest” bit, with the maximum clearance possible. If drilling a chemical alternative is available, spotting a 1-5% caustic solution (depending on the BHST), soaking for 20 minutes to break the resin bonds between the proppant grains and then washing the unconsolidated circulating with coiled tubing or jointed pipe.

Get access

Please fill out the form to continue reading

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.

Get access

Please fill out the form to continue reading

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.

Join Us

Subscribe our newsletter and stay

up to date about the company

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.