Microproppant

Increase operational efficiencies during stimulation and enhance well-productivity

with CARBO’s microproppant, NANOMITE Express.

Unlock Efficiency and Productivity in Hydraulic Fracturing

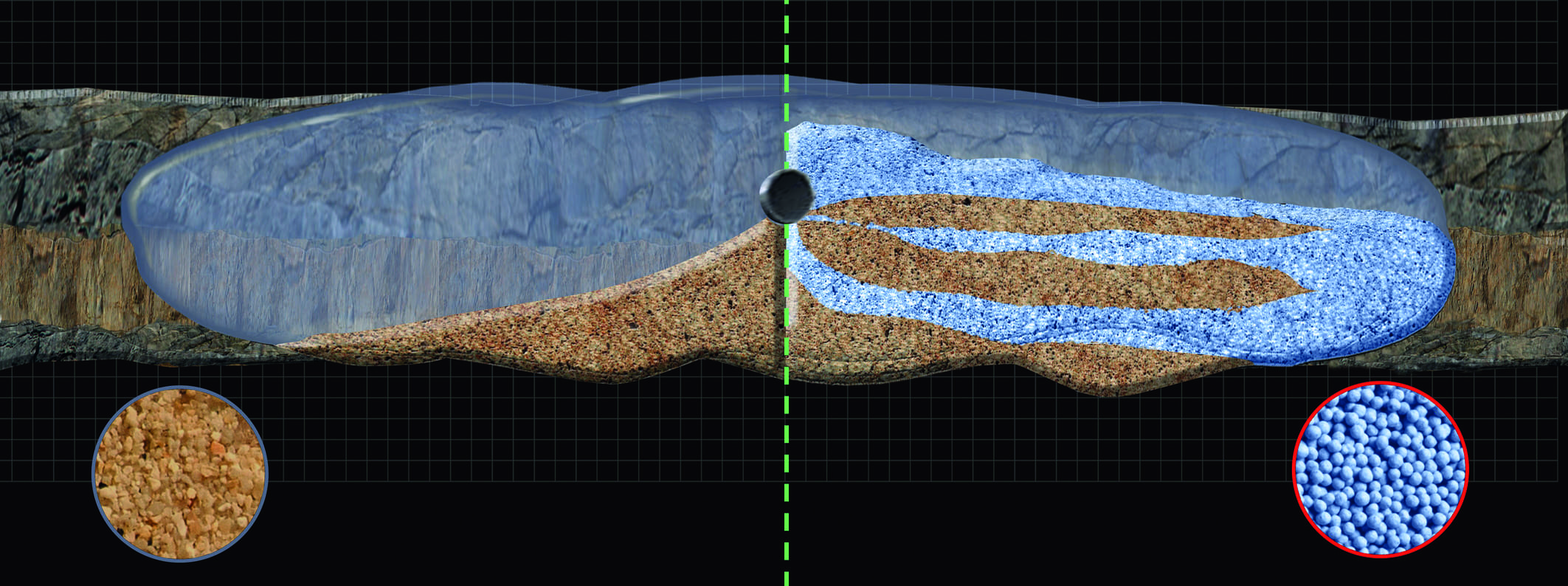

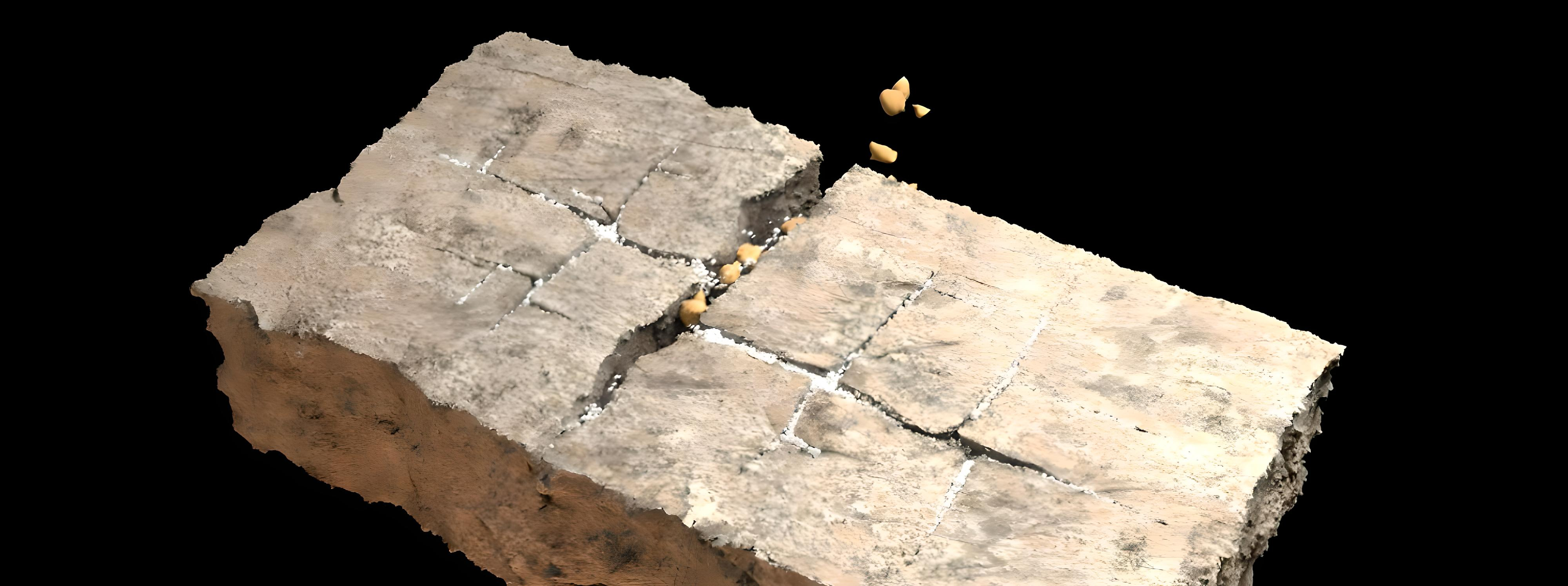

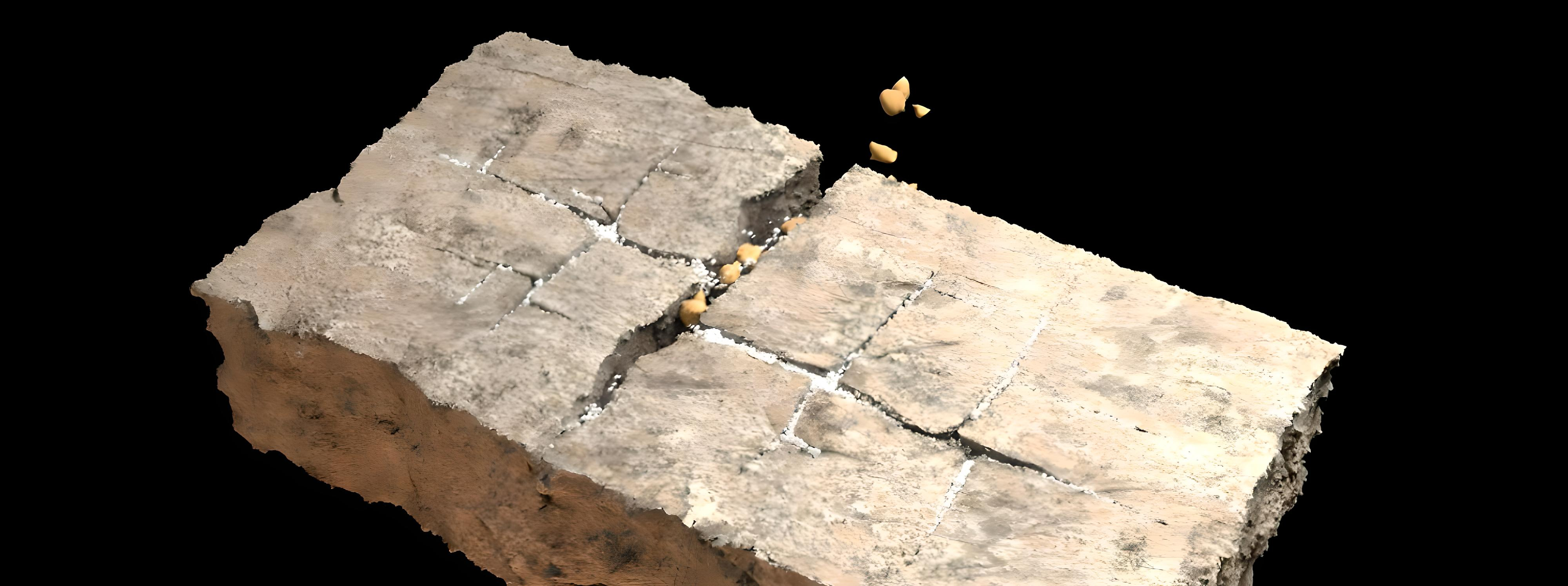

NANOMITE Express, CARBO’s innovative microproppant solution, is designed to enhance efficiency and well productivity in hydraulic fracturing operations. This high-strength, ceramic microproppant is engineered with a fine particle size distribution averaging 325 mesh, making it uniquely suited to prop open microfractures that remain untreated by traditional proppants. Delivered in pelletized form, it offers superior flowability and is compatible with standard pumping equipment, making it an operationally efficient and cost-effective choice.

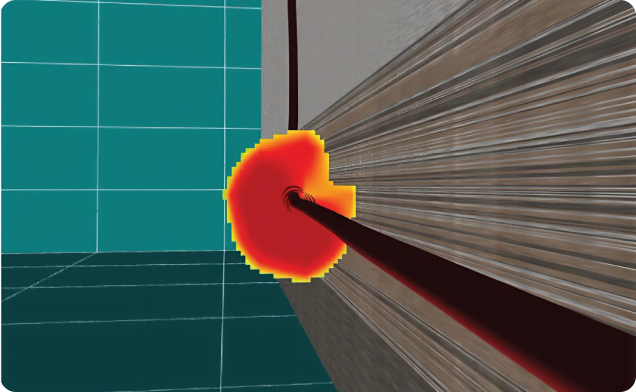

One of the primary benefits of NANOMITE Express lies in its ability to penetrate deep into complex fracture networks. It’s extremely low settling velocity and broad particle size range allow it to travel further into fractures, even in thin fluids like freshwater or slickwater. This ensures the effective propping of microfractures, significantly increasing the stimulated reservoir volume. As a result, operators can achieve greater connectivity between the reservoir matrix and fracture network, leading to higher hydrocarbon recovery and improved overall production.

The use of NANOMITE Express also reduces operational challenges and costs. By mitigating fracture entry restrictions and pressure-dependent leak-off (PDL), the microproppant lowers the risk of early screen-outs and reduces surface treating pressures. This enables faster completions, lower fuel costs, and reduced horsepower requirements, all of which contribute to substantial cost savings. Additionally, its pelletized form minimizes dust exposure, reducing health, safety, and environmental risks.

Field trials and case studies have consistently demonstrated the effectiveness of NANOMITE Express, showing production uplifts of up to 24% in various formations. With its ability to enhance fracture coverage, improve well performance, and optimize completion efficiency, NANOMITE Express represents a transformative solution for the fracking industry, unlocking additional hydrocarbon volumes and ensuring long-term productivity.

Frequently Asked Questions

Everything You

Need to Know

-

What is NANOMITE Express microproppant?

NANOMITE Express is a high-strength ceramic microproppant designed for hydraulic fracturing operations. It features an ultra-fine particle size distribution (average 325 mesh) that allows it to prop open microfractures that conventional proppants cannot effectively treat.

-

What are the key benefits of using NANOMITE Express in fracking operations?

NANOMITE Express enhances fracture stimulation by:

- Expanding the connected fracture network to improve hydrocarbon recovery.

- Reducing near-wellbore friction, treating pressure, and completion time.

- Mitigating early screen-outs and pressure-dependent leak-offs.

- Improving proppant placement efficiency and overall operational cost-effectiveness.

-

How does NANOMITE Express improve operational efficiency?

This microproppant has a broad particle size range and low settling velocity, enabling deeper penetration into fracture networks. It reduces treating pressures and enhances proppant transport, lowering pumping times and fuel costs while minimizing health, safety, and environmental risks.

-

Can NANOMITE Express be used with standard pumping equipment?

Yes, NANOMITE Express is designed to be delivered as a traditional proppant. Its pelletized form enhances flowability and allows it to be pumped using existing equipment without the need for special handling or slurry preparation.

-

What makes NANOMITE Express unique compared to traditional proppants?

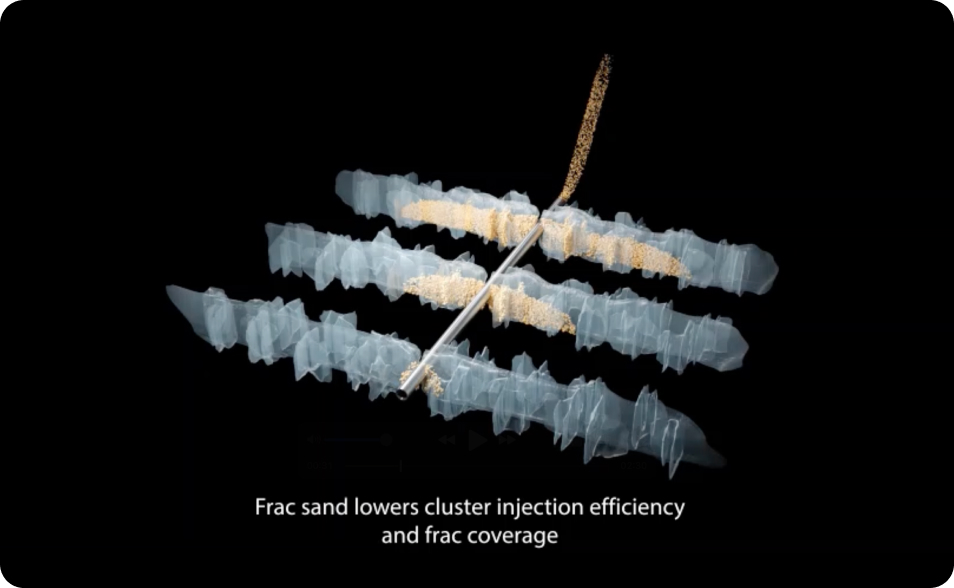

Unlike traditional proppants, NANOMITE Express:

- Has an average settling velocity 11 times slower than 100-mesh frac sand.

- Props microfractures more effectively, increasing the stimulated reservoir volume.

- Reduces fracture tortuosity, improving cluster injection efficiency and fracture coverage.

-

What impact does NANOMITE Express have on production outcomes?

Field trials have shown production uplifts of up to 24% in formations like the Bakken. The enhanced proppant distribution within the reservoir matrix ensures a greater contribution to hydrocarbon production, increasing long-term well productivity.

-

How does NANOMITE Express improve health, safety, and environmental (HSE) compliance?

The microproppant’s pelletized design minimizes dust exposure during handling, reducing HSE risks compared to alternative proppant solutions.

-

Is NANOMITE Express cost-efficient?

Yes, NANOMITE Express offers significant cost savings by reducing completion times, fuel consumption, and horsepower requirements. It also eliminates the need for expensive slurry preparation, further enhancing its cost-effectiveness.

-

What fluid systems can NANOMITE Express be used with?

NANOMITE Express is compatible with thin fluid systems, such as freshwater and slickwater, making it versatile for various hydraulic fracturing operations.

-

How does NANOMITE Express compare to alternative microproppant products?

NANOMITE Express outperforms alternatives by offering greater durability, better fracture conditioning, and enhanced long-term productivity at a lower total cost. It has been proven across multiple formations to deliver superior operational and production benefits.