CARBONRT ULTRA

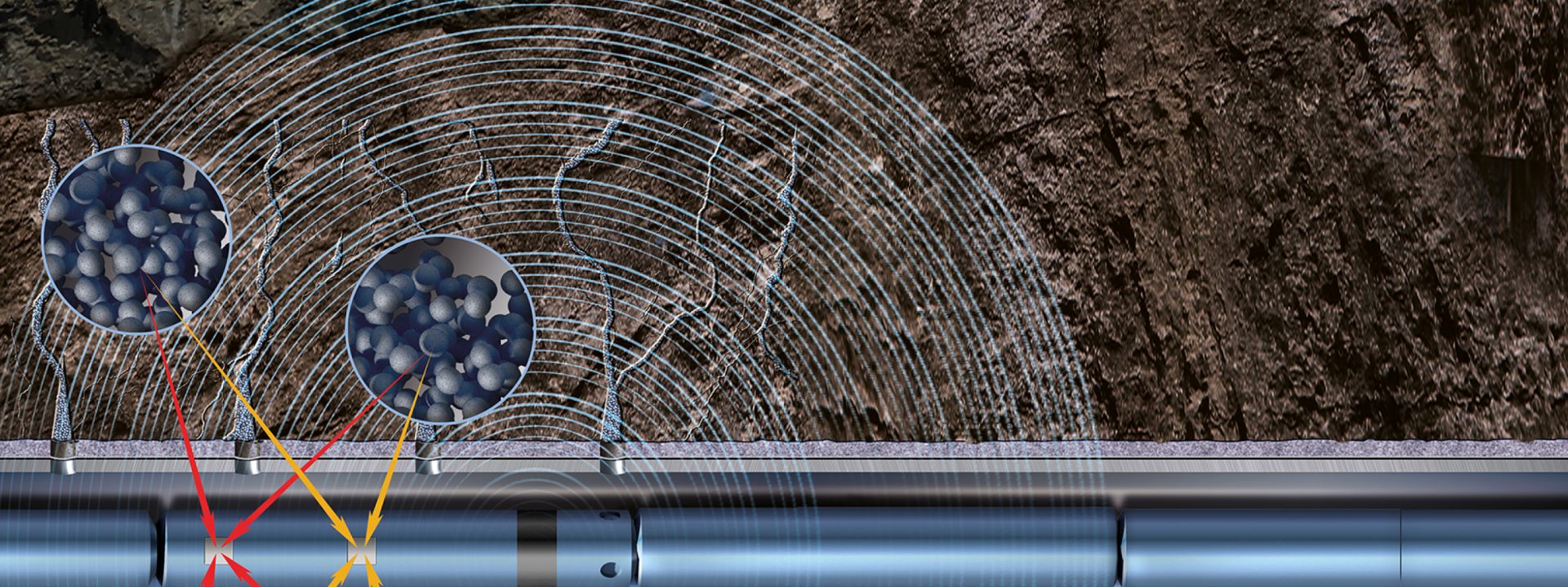

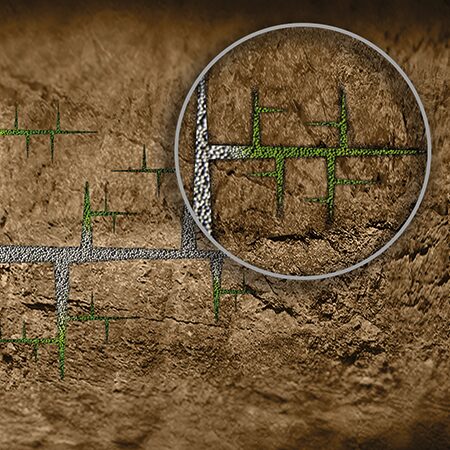

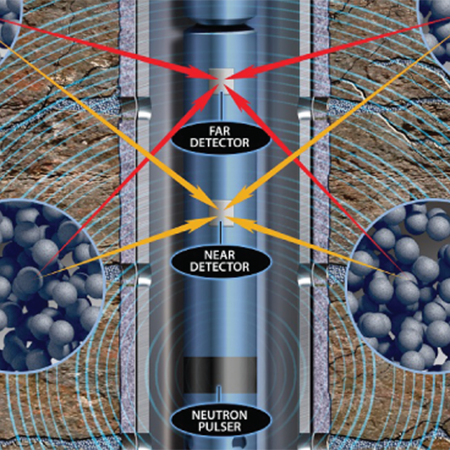

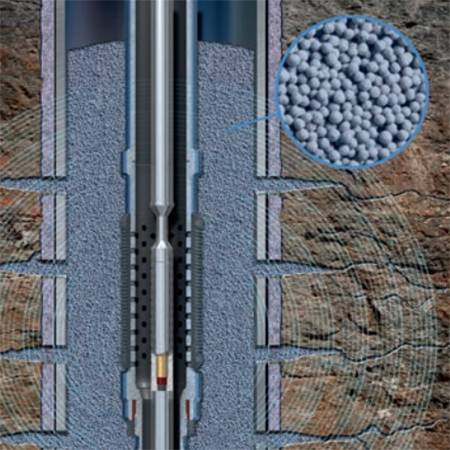

CARBONRT ULTRA inert tracer technology has been developed to enable the cost-effective fracture evaluation of sand completed wells to help you optimize completion efficiency, production and field development. The unique non-radioactive tracer (NRT) technology enables the effective detection and evaluation of near-wellbore proppant location and quantity using our FRACTUREVISION proppant-delivered fracture evaluation service at any time during the life of the well.