NANOMITE

The unique characteristics of NANOMITE ceramic microproppant reduces completion time, screen-out risks, and overall completion costs while improving the production contribution from all clusters and the reservoir matrix.

At Carbo Ceramics, we provide cutting-edge solutions tailored to the unique

demands of the Oil and Gas industry.

Mission Statement

(Source: IEA, 2022)

3.2 Gt

Of CO2 equivalent emissions per year from the global oil and gas sector

(Source: Rystad Energy, 2023)

42%

Rise in operational downtime due to equipment failures, despite a 15%

increase in production efficiency

(Source: Rystad Energy, 2023)

68%

Enhancement in recovery rates for deepwater drilling projects, compared to a 25% increase in shallow-water projects

Oil&Gas Solutions

Our Base Ceramics products are engineered to deliver exceptional proppant performance in oil and gas completions.

Ultra-conductive proppant technologies are engineered to deliver superior conductivity, enhancing hydrocarbon flow and maximizing well productivity.

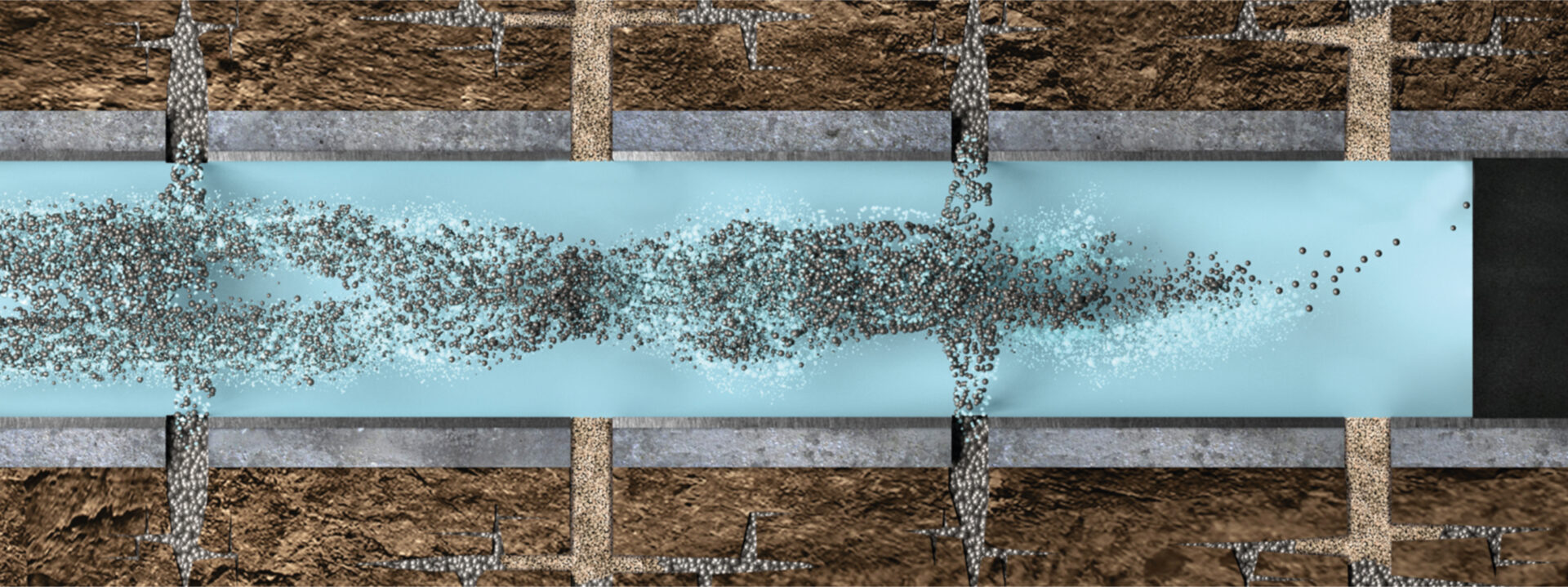

CARBOAIR’s high transport proppant family represents a breakthrough in proppant technology, engineered to enhance well performance by improving proppant transport and distribution in hydraulic fractures.

Avoid proppant pack washouts, voids, and loss of wells with CARBO’s proppant pack consolidation technology.

Avoid proppant pack washouts, voids, and loss of wells with CARBO’s proppant pack consolidation technology.

Most conventional proppants are naturally water-wet, characterized

by a contact angle of less than 90°.

Protect your production system with our line of GUARD products.

CARBONRT product family leverages advanced inert tracer technologies to provide real-time fracture evaluation and proppant tracking, delivering critical insights for well optimization.

Production Tracers are an advanced monitoring tool used in oil and gas operations to gain real-time insights into the behavior of fluids within a reservoi

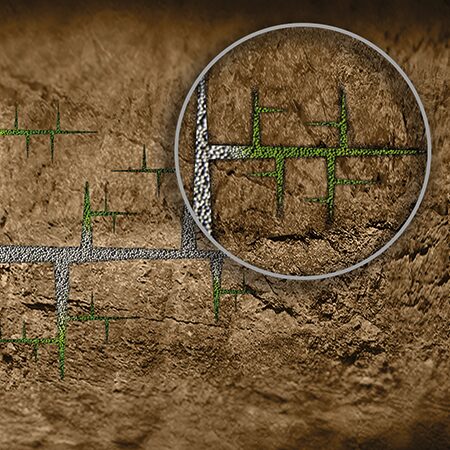

In the oil and gas industry, poor near-wellbore diversion often results in uneven stimulation treatments and suboptimal hydrocarbon recovery.

Our Frac Sand offerings are among the purest and most consistent sand on the market, ensuring high conductivity.

Our products

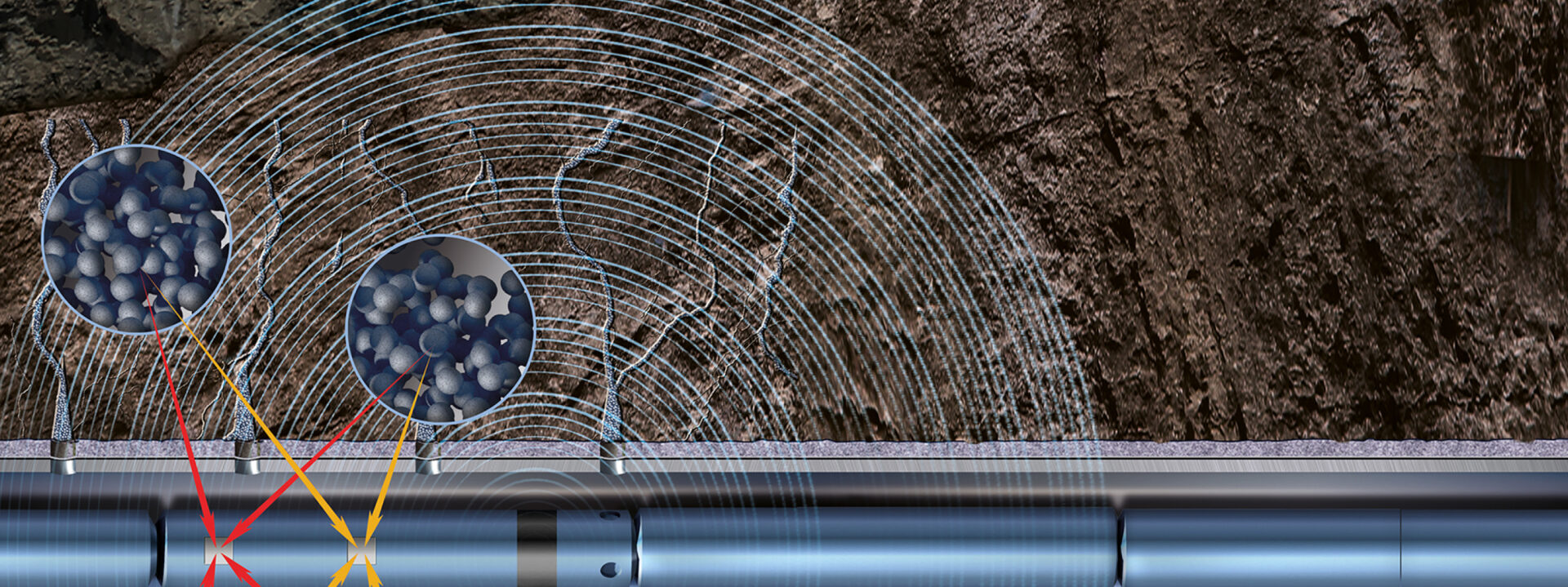

NANOMITE

The unique characteristics of NANOMITE ceramic microproppant reduces completion time, screen-out risks, and overall completion costs while improving the production contribution from all clusters and the reservoir matrix.

SCALEGUARD

SCALEGUARD proppant-delivered scale-inhibiting technology is a porous ceramic proppant engineered with an innovative controlled release technology and infused with scale-inhibiting chemicals.

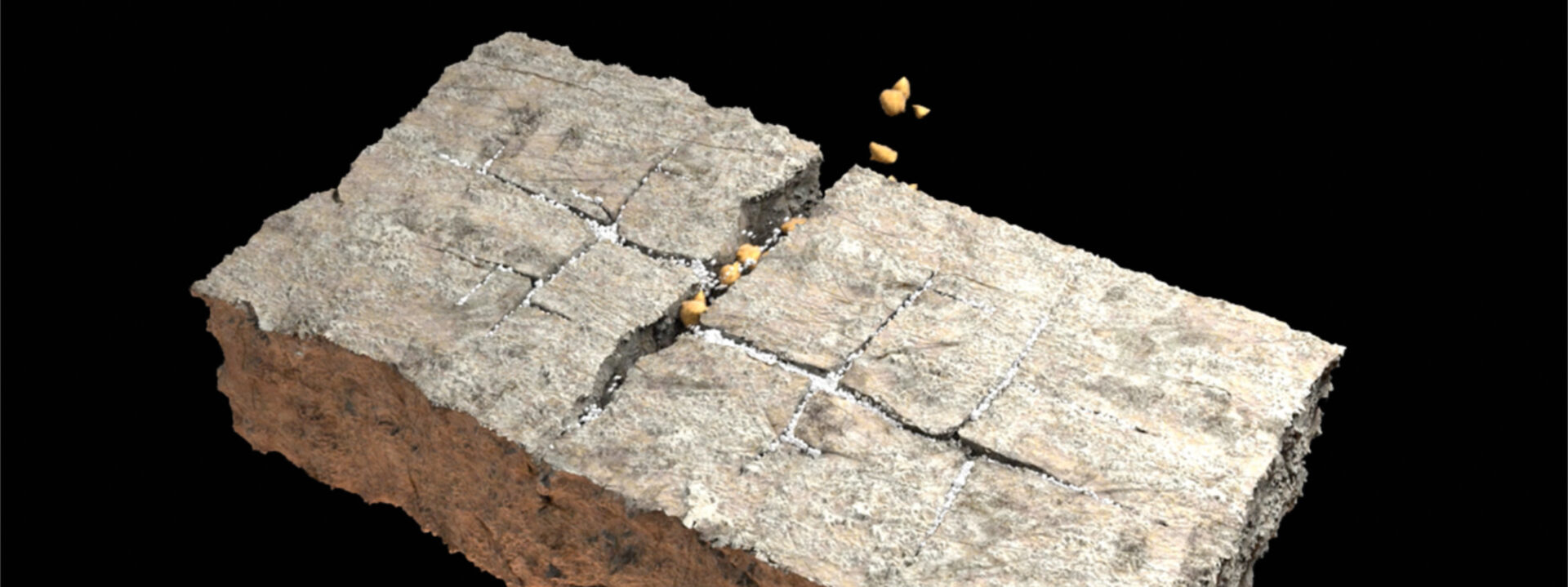

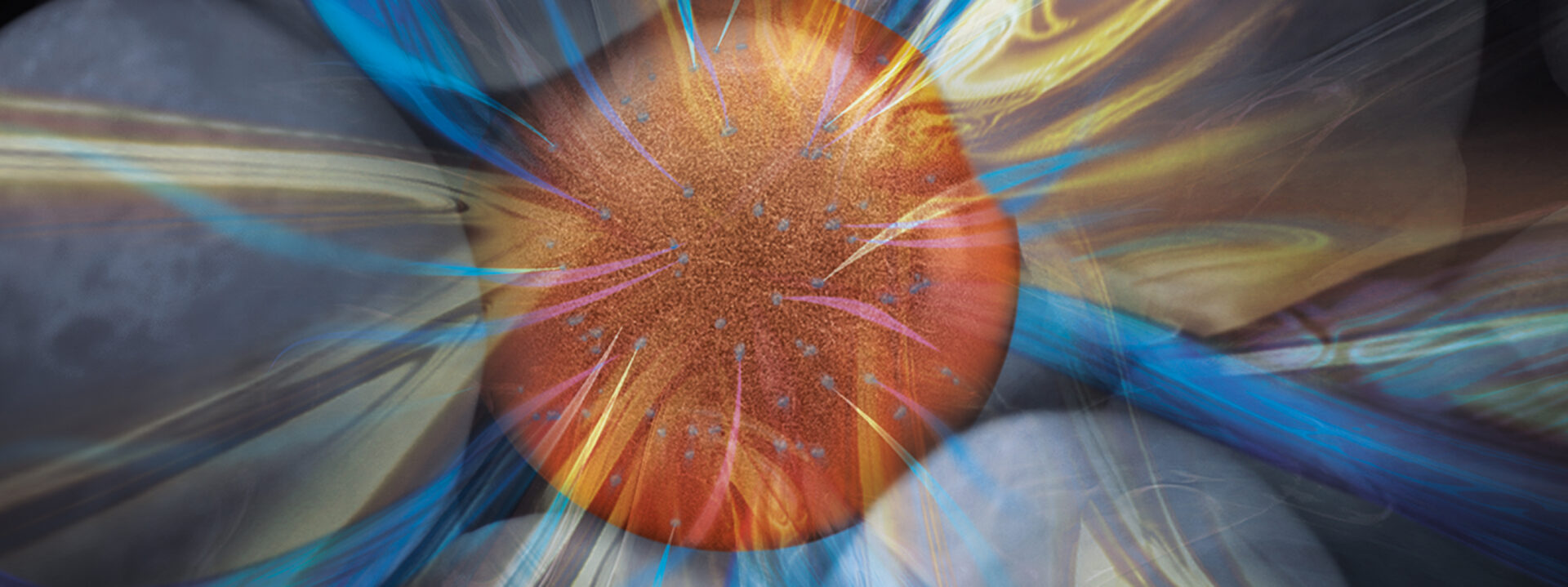

KRYPTOSPHERE HD

KRYPTOSPHERE HD ultra-conductive, high-density ceramic proppant technology has been specifically engineered for high closure stress and risk environments, including ultra deepwater regions such as the Gulf of Mexico.

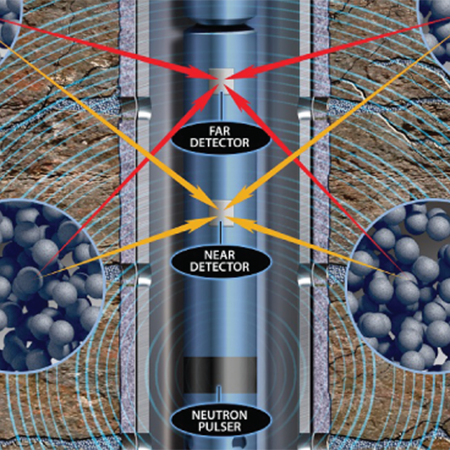

CARBONRT

CARBONRT inert tracer technology for ceramic completed wells

FUSION

With FUSION proppant pack consolidation technology you can now create a bonded, high integrity proppant pack with or without closure stress.

CARBOTRACE

CARBOTRACE Production surveillance integrated with CARBO quality proppants.

Representatives

Our Oil & Gas industry specialists are ready to assist with your inquiries. With expert knowledge and tailored solutions, we’ll help you achieve your goals. Contact us today!

Darryl Cooper

Tim Kriegshauser

Pedro Saldungaray

Enrico Annovi

Eduardo Velez

Dina Goloshchapova

Explore CARBO’s comprehensive range of advanced

products designed specifically for the mining industry.

Resources

Frequently Asked Questions

Is your tracer proppant radioactive?

The tracer in CARBONRT traceable proppant is non-radioactive. Key benefits of the CARBONRT technology are its reduced HSE footprint, simplified logistics, handling and disposal derived from its inert nature, as compared to the inconvenience of using conventional Radioactive (RA) tracers.

What is the difference between frac sand and frac proppant?

While “sand” is a natural mined product, a “frac proppant,” or ceramic proppant, is an engineered manmade product. As such, ceramic proppants are manufactured in varying grades with properties to match the reservoir conditions they will be applied at. They key features of ceramic proppants with respect to regular sands are their superior strength and conductivity that results in higher production, hydrocarbon recovery, and return on investment for the treated well.

What is infused proppant?

Infused proppants are proppants impregnated with production assurance chemistries grouped under the GUARD technology platform. They are placed as a part of a hydraulic fracture, fracpack, or gravel pack treatment and release the impregnated chemical over time as production stream flows from the formation to surface facilities. CARBO currently provides SCALESGUARD to prevent carbonate and sulphate scales, SALTGUARD for halite inhibition, ASPHALTENEGUARD for asphaltene prevention. We are actively working on incorporating additional chemistries.

How small is a microproppant?

NANOMITE microproppant has a 325 mesh or 45 μm mean particle size. The unique characteristics of this microproppant enables propping natural and induced micro-fractures, reducing entry restrictions, reducing pressure-dependent leakoff (PDL), as well as far field diversion. These features help increase initial production and mitigate decline; reduce treating pressure, treating time, HHP, fuel and FR requirements; and maximize placement.

NANOMITE Express is a pelletized form of NANOMITE that allows the microproppant to be delivered as a traditional proppant and to enhance operations minimizing dusting and improving flowability in dry form.

What are the benefits of using CARBO’s ceramic proppants?

Sand and ceramics are the most widely used proppants. While sand is a natural mined product, ceramic proppant is an engineered manmade product with superior strength and conductivity. As a results, ceramic proppants yield higher production, hydrocarbon recovery and return on investment for the treated well.

Can proppant be pumped in Geothermal wells?

Yes, ceramic proppants can be pumped in Geothermal wells. Its superior thermal stability and reduced solubility in HT freshwater environments to make them the preferred option over sand.

Can you pump frac sand and proppant on the same well?

Yes, sand and ceramic proppants are routinely pumped in combined treatments. Sand is pumped in the initial or “lead” stages and placed towards the tip of the frac where it will be subject to lower stress and where lower conductivity is required. CARBO ceramic proppant is used in the final or “tail” stages on the frac, to be placed nearer to the wellbore where it will be subject to the highest stress and where more conductivity is required to handle the contribution to the whole frac length and flow concentration (the latter in the case of transverse fracs).

What type of containers do you ship proppant in?

CARBO ships proppant in regular 20 ft containers. Depending on regulations, we fit 14 to 18 bulk bags, individually weighing 1.5 MT (3,307 Lb), in each container for a total load between 21 and 27 MT (69,447 – 89,289 Lb).

Can Carbo make any mesh size proppant?

Yes, CARBO makes any size proppant from microproppants (325 mesh) to very large mesh sizes, such as 6/14 mesh. CARBO manufactures proppants both in regular API sizes and monomesh, ultra-conductive proppants, which fall under the KRYPTOSPHERE technology family. The most common sizes are 40/70, 30/50, 20/40, 16/20, 16/30 and 12/18 API sizes, and monomesh 35, 25, 20, and 18.

Why is closure stress important for proppant in a well?

Closure stress is the determining factor in proppant conductivity and therefore the productivity of the fractured well. The Effective Stress on proppant must be used in this assessment, which is the Closure Pressure (zone depth in TVD * frac gradient), minus the pressure inside the frac (typically the bottom hole flowing pressure which is the lowest pressure in the frac system and carries part of the stress), plus the Net Pressure developed during the treatment.

How does proppant help protect the production equipment in a well?

Proppant will prevent the production of formation sand in gravel packs, fracpacks and regular fracs, hence protecting completion, artificial lift and production equipment.

Get access

Please fill out the form to continue reading

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.

Get access

Please fill out the form to continue reading

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.

Join Us

Subscribe our newsletter and stay

up to date about the company

Thank you for completing the form!

We appreciate your interest and look forward to providing you with

valuable content.